If you’ve ever noticed those lines or gaps in the concrete of buildings, roads, or bridges, you’ve encountered joints. These joints play a crucial role in ensuring the structural integrity and durability of various structures.

Joints combine two distinct pieces into a single unit. However, as you are probably aware, the “Joint” is a structure’s weakest area, therefore if possible, avoid it.

The majority of construction components are made of various materials and may shrink or expand depending on the weather. To stop concrete fractures caused by weather conditions, many types of joints are employed.

In this article, we’ll delve into the key differences between expansion joints, contraction joints, and construction joints, shedding light on their distinct purposes and functions.

Contents

Types of Joints in Construction

- Construction Joints

- Expansion Joints

- Contraction Joints

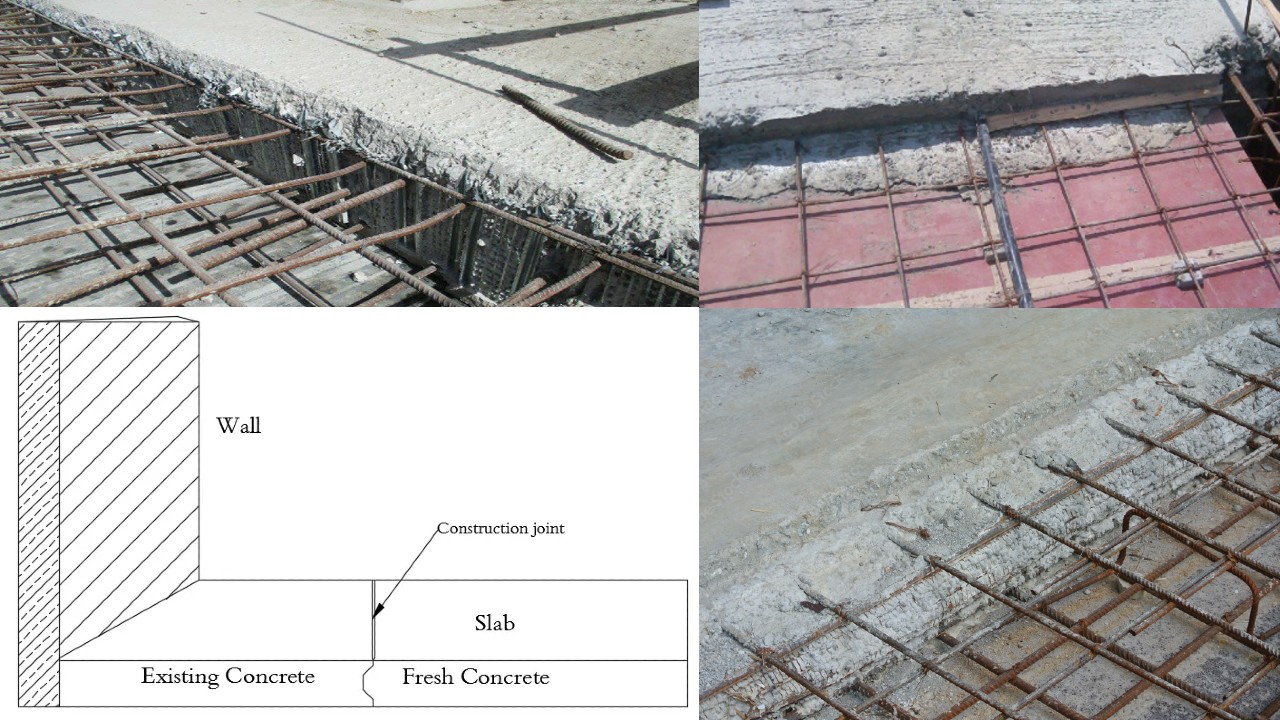

Construction Joints

A bigger amount of concrete cannot be poured at once. As a result, at that point, a specific section had been poured in accordance with the suggested shuttering design, and the remaining portion would be poured later.

Construction joints are formed when concrete pouring is temporarily interrupted, resulting in two separate sections of concrete that need to be joined together. These joints allow work to proceed in phases and ensure proper bonding between the two sections.

In that, construction joints, also known as cold joints, are utilized to link the new and old concrete.

Applications of Construction Joints

Construction joints are typically found in vertical structures like walls and columns, as well as in horizontal applications such as slabs. They are essential for managing the construction process efficiently.

Positive Aspects of Construction Joints

Construction joints facilitate construction in stages, enabling better quality control and reducing the risk of cold joints, where new concrete doesn’t properly adhere to the existing concrete. They ensure structural integrity and consistency in the project.

Specification of Construction Joints

- The surface of the concrete should be uneven and dust-free.

- To create the right connection between the old and new concrete, a suitable vibration must be performed close to the junction.

- After placing new concrete, the joint surface has to be wire-brushed clear of laitance and slurry.

- Construction joints are offered in accordance with IS 11817.

Construction Joint in Concrete Works

Source: Learning Civil Technology

Expansion Joints

As we previously explained, many raw materials are processed into construction materials. The weather condition may cause the concrete to contract or expand.

We employ expansion joints to prevent any structural collapse brought on by the deformation of building materials. The expansion joints gap is designed to tolerate movement caused by expansion or shrinkages while preventing structural disfigurement.

Large structures like bridge girders typically include expansion joint gaps to distribute potential stresses. The expansion substance, such as fiber, bitumen, or any other unique material, fills the joint gaps.

Expansion joints, also known as movement joints, are deliberate gaps in structures that allow them to expand and contract in response to temperature changes, humidity, and external forces. These joints absorb the stress and movement that occur due to these factors, preventing cracks and damage.

Application of Expansion Joints

Expansion joints find applications in various structures, including buildings, bridges, highways, and pipelines. They accommodate movement in structures such as buildings that experience thermal expansion and contraction.

Benefits of Expansion Joints

By accommodating movement, expansion joints help to maintain the structural integrity of a building or structure. They prevent the formation of cracks and ensure that the overall stability of the structure is not compromised.

Specification of Expansion Joints

- In bridges, an expansion joint may be included in the middle of each span.

- Expansion joints must be provided when a structure is longer than 45 meters.

- The expansion joint area shouldn’t receive any reinforcements.

- Depending on the construction, a different expansion joint material will be used.

- The expansion joints are offered in accordance with IS 3414.

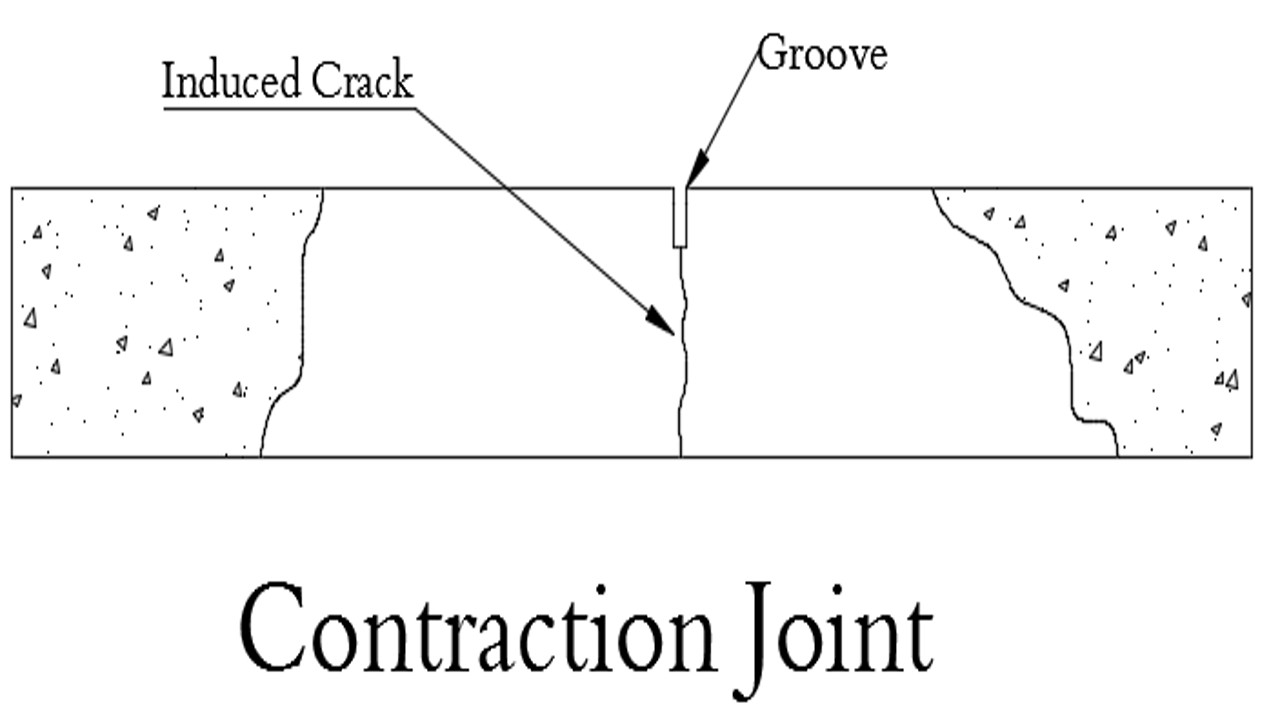

Contraction Joints

It is a different kind of joint that prevents cracks from forming as a result of shrinkages. Where a fracture in concrete could develop, the contraction joints are positioned like a groove. Contraction joints stop a shrinkage crack from spreading to another region if it develops in a concrete slab.

Contraction joints, also known as control joints, are intentional breaks in concrete that influence the location of cracks as the concrete contracts during the curing process. They dictate where the cracks will occur, ensuring they happen in a controlled and predictable manner.

Application of Contraction Joints

Contraction joints are commonly found in concrete pavements, flooring, and other large concrete surfaces. They help control the cracking that inevitably happens due to the concrete’s contraction.

Advantage of Contraction Joints

These joints prevent random cracking, which can be unsightly and potentially compromise the concrete’s durability. By controlling where the cracks occur, contraction joints maintain the structural integrity and aesthetic appearance of the concrete surface.

Specification of Contraction Joint

- The groove’s width shouldn’t be any less than 5mm.

- The depth of the contraction joint is one-fourth of the mean depth of concrete.

- It ought to be put in the area of the slab that is weakest.

- The contraction joint is also known as the control joint.

Conclusion

Expansion joints, contraction joints, and construction joints each serve distinct yet critical roles in maintaining the structural integrity and longevity of various concrete and other construction projects. While expansion joints accommodate movement, contraction joints control cracking, and construction joints enable phased construction. It’s important to consider these differences and select the appropriate joints based on factors such as structure type, location, and anticipated movement. By doing so, we ensure safer, more durable, and aesthetically pleasing structures that stand the test of time.

Frequently Asked Questions (FAQs)

What is the main purpose of expansion joints?

Expansion joints allow structures to expand and contract without causing damage, preventing cracks and maintaining stability.

Are contraction joints only used in concrete pavements?

No, contraction joints are also used in other concrete surfaces like floors and slabs to control cracking.

Can construction joints weaken a structure?

When properly designed and executed, construction joints do not weaken a structure. They are essential for phased construction.

How frequently should expansion joints be inspected?

Regular inspections, ideally annually, help identify any deterioration or issues with expansion joints.

Are there cases where all three types of joints are used together?

Yes, complex structures may require a combination of expansion, contraction, and construction joints to address various types of movement and construction needs.