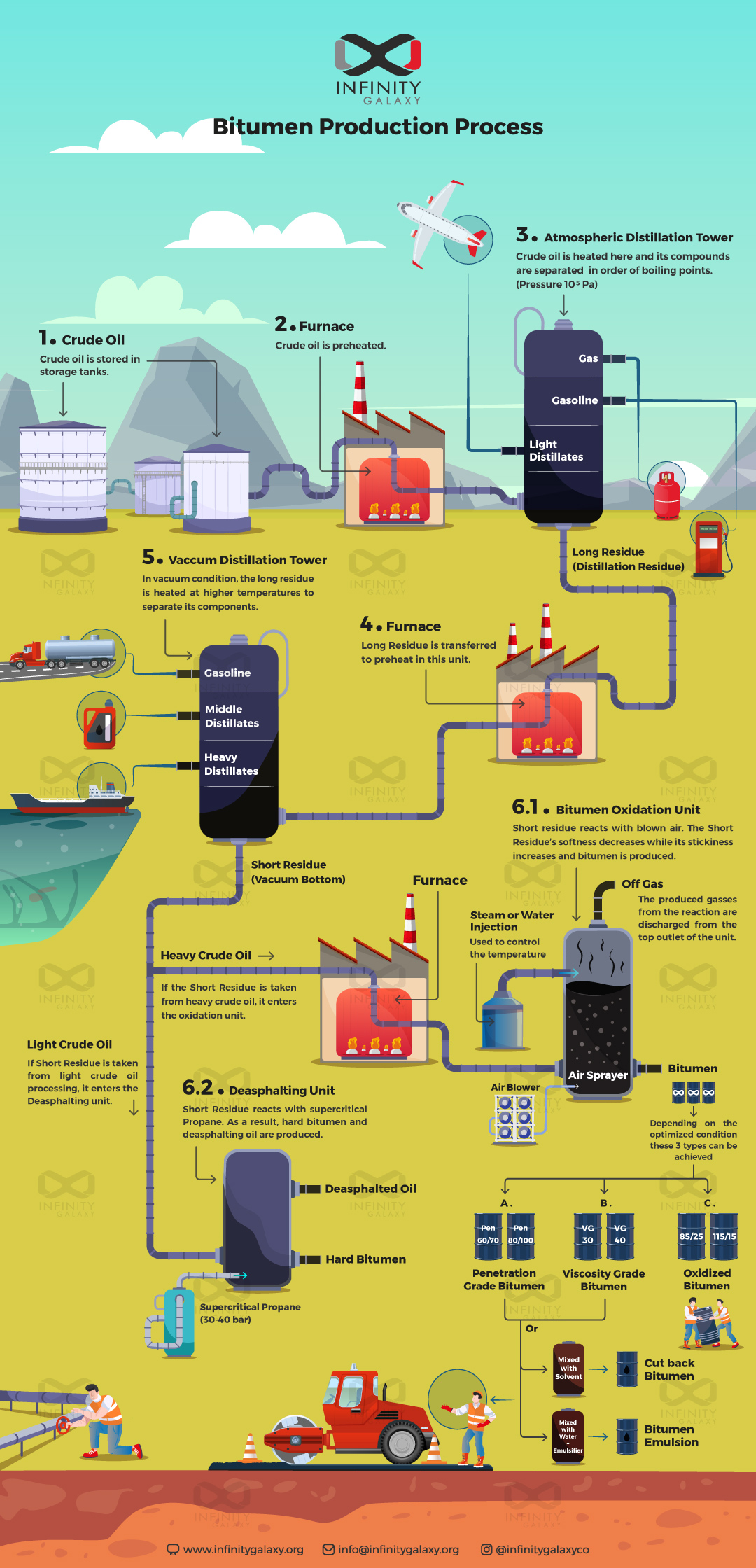

Bitumen, the main material in different industries, especially road construction, can be produced in the refinery. There are several types of bitumen production methods as below:

- Straight Run

- Air Blowing

- Deasphalting

- Blending

The most common way of bitumen production process is air blowing. The method that is not very common and is done in some European refineries is blending.

If you are interested in knowing the bitumen production process, follow this post.

We will explain the Air Blowing bitumen production process.

Air Blowing Bitumen Production Process

Bitumen, like every other material, has a raw material. The raw material of bitumen is vacuum bottom.

This vacuum bottom is obtained from the crude oil distillation. Generally, when the crude oil comes from the pipelines to the crude oil refinery, it enters the desalter. In desalter, its salt will be removed. The salt free crude oil will pass through different equipment like heat exchangers, condensers and other equipment.

Then it enters the atmospheric distillation tower. In this tower, there exist different trays. The different components of crude oil will separate in each tray based on their boiling point.

The lighter components separate in the higher trays and the heavy components will remain as the long residue.

After passing through the furnace, the long residue will enter the vacuum distillation tower. In this tower, same as atmospheric distillation tower, there are some trays. The component of the long residue separates here and the remaining material will be the short residue or vacuum bottom.

In this step, it is important to know that the crude oil which is used first is a heavy type crude oil or light one.

If the short residue is the output of the heavy crude oil, it should be transferred by pipelines to the oxidation unit of the refinery.

Oxidation Unit

In this unit, the hot air is passing through the short residue in the tower.

The oxygen molecules react with the vacuum bottom. This causes the separation of hydrogen and oxygen atoms and cyclic molecules are generated.

The result of this unit is different types of bitumen including bitumen penetration, viscosity bitumen and oxidized or blown bitumen.

De-asphalting Unit

If the short residue is the output of light crude oil, it enters the de-asphalting unit. In this unit, the short residue reacts with the supercritical propane. The result of this unit is the de-asphalted oil and hard bitumen.

In the Infographic below which is prepared by Infinity Galaxy, the bitumen production process is shown: