AGGREGATE IMPACT VALUE TEST

Object of the Experiment

To evaluate the toughness of a stone i.e. the resistance of the aggregates to fracture under repeated impacts is called Impact Test. This test is done to determine the aggregate impact value of coarse aggregate as per IS 2386 (Part-IV) 1993. Aggregate Impact Value Test as per IS 2386 (Part-IV) 1993

Theory and Scope

The property of a material to resist impact is known as toughness. Due to movement of vehicles on the road, the aggregates are subjected to impact resulting in their breaking down into smaller pieces. The aggregate should therefore have sufficient toughness to resist their disintegration due to impact. This characteristic is measured by Impact Value Test. The aggregate impact value is the measure of resistance to sudden impact of shock, which may differ from its resistance to gradually applied compressive load.

Equipments

The apparatus as per IS 2386 (Part-IV) 1993 consist of,

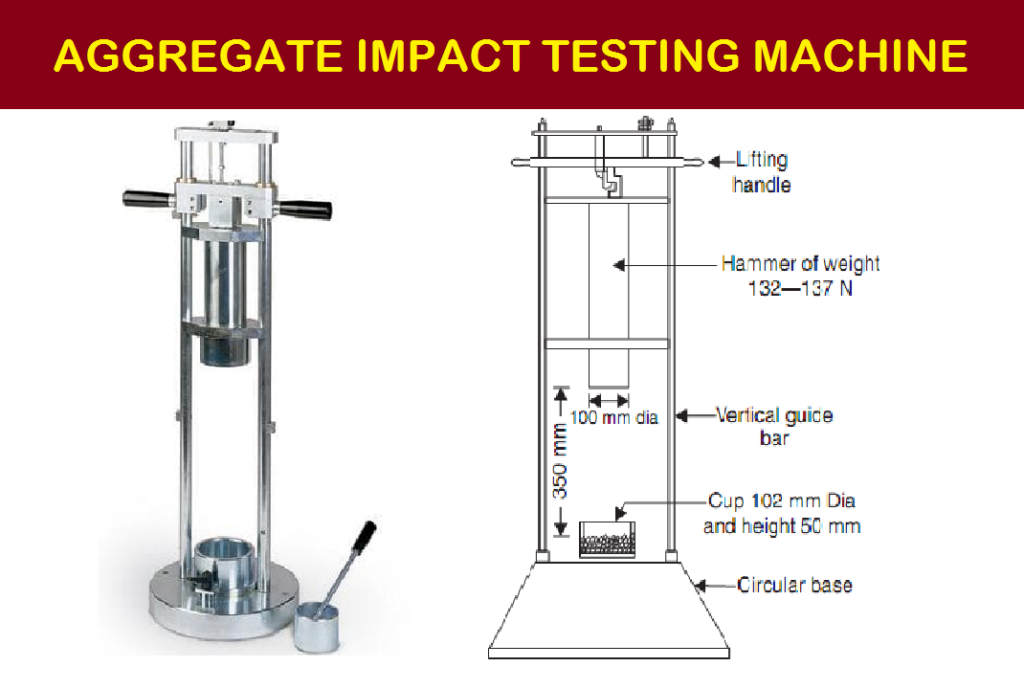

Impact Testing Machine : A testing machine weighing 45 to 60 Kg and having a metal base with a heavy lower surface of not less than 30 centimetre in diameter. It is supported on plane and level concrete floor of minimum 45 cm thickness. The machine should have provision for fixing its base.

A cylindrical Steel cup of internal diameter 102 mm, depth 50 mm and minimum thickness of 6.3 mm.

A metal hammer weighing 13.5 to 14.0 Kg, the lower end being cylindrical in shape, 50 mm long, 100 mm in diameter with a 2 mm chamfer at the lower edge and case hardened.

The hammer should slight freely between vertical guides and be concentric with the cup. Free fall of hammer should be within 380 ± 5 mm.

A cylindrical metal measure having internal diameter 75 mm and depth 50 mm for measuring aggregates.

Tamping rod 10 mm diameter and 230 mm long rounded at one end.

A balance of capacity not less than 500 gram, readable and accurate up to 0.1 gram.

ALSO READ

- Aggregate Crushing Value Test

- Water Content of Soil by Oven Drying Method

- Specific Gravity of Cement by Specific Gravity Bottle

- Sp. Gravity & Water Absorption Of Coarse Aggregate

- Sp. Gravity & Water Absorption of Fine Aggregates

Procedure

The test sample consist of aggregates sized 12.5 mm to 10 mm. Aggregates may be dried by heating at 100 degree Celsius to 110 degree Celsius for a period of 4 hours and cooled.

1. Save the material through 12.5 mm and 10 mm IS sieves. The aggregate passing through 12.5 mm sieve and retained on 10 mm sieve comprises the test material.

2. Pour the aggregate to fill about just one third depth of measuring cylinder.

3. Compact the material by giving 25 gentle blows with the rounded end of the tamping rod.

4. Add two more layers in similar manner, so that the cylinder is full.

5. Strike off the surplus aggregates.

6. Determine the net weight of the aggregate to the nearest gram (W1).

7. Fix the cup with the test sample firmly in position on the base of machine.

8. Raise the hammer until its lower face is 380 mm above the surface of aggregate sample in the cup and allow it to fall freely on the aggregate sample. Give 15 such blows at an interval of not less than one second between successive falls.

9. Remove the crushed aggregates from the cup and sieve it through 2.36 mm IS sieve until no further significant amount passes in one minute. Weigh the fraction passing the sieve (W2) to an accuracy of 1 gram.

Compute the aggregate impact value. The mean of 2 observations, rounded to nearest whole number is reported as the aggregate impact value.

Observations and Calculations

|

Specimen No. |

Mass of Sample of Aggregate, W1 gm | Quantity of Sample Passing 2.33 mm IS sieve, W2 gm | Percentage Passing = (W2/W1)x100 |

|

1 |

|||

|

2 |

Result

Aggregate Impact Value = ……………………………………………

Discussions

Classification of aggregates using aggregate Impact Value is as given below :

|

Aggregate Impact Value (%) |

Classification |

|

< 10 |

Exceptionally Strong |

|

10 – 20 |

Strong |

|

20 – 30 |

Satisfactory for Road Surfacing |

| > 35 |

Weak for Road Surfacing |

Specified limits of percent aggregate impact values for different types of road Construction by IRC are given below :

|

SL No. |

Types of Pavement |

Aggregate Impact Value not more than |

|

1. |

Bituminous Concrete | 24 |

|

2. |

Dense bituminous macadam, Semi-dense bituminous concrete, Surface dressing, Bituminous carpet and cement Concrete wearing course |

27 |

| 3. | Wearing course |

30 |

|

4. |

Bitumen bound macadam base course | 35 |

|

5. |

WBM base course with bitumen surfacing |

40 |

| 6. | Cement concrete base course |

45 |

Conclusion

After carried out the Impact Test, we can conclude that the sample has an Aggregate Impact Value of ………………………………………………