Dr. Fixit Roofseal is a single component cold applied elastomeric waterproofing coating based on synthetic resin emulsion. It is a tough yet extremely flexible coating that can be efficiently applied by roller or squeegee.

Contents

- 1 Typical Applications – Dr. Fixit Roofseal Waterproofing

- 2 Features

- 3 Packaging

- 4 Method of Application – Dr. Fixit Roofseal Waterproofing

- 5 Precautions & Limitations – Dr. Fixit Roofseal Waterproofing

- 6 Technical Information – Dr. Fixit Roofseal Waterproofing

- 7 Theoretical Coverage – Dr. Fixit Roofseal Waterproofing

- 8 Shelf Life

- 9 Health & Safety

- 10 Check Price on Amazon – Dr. Fixit Roofseal Waterproofing

Typical Applications – Dr. Fixit Roofseal Waterproofing

Waterproofing of flat concrete roofs.

Features

Waterproofing – High film build up provides excellent water resistance

Elastomeric – Excellent flexibility and elongation properties – can easily accommodate all normal building

movements.

Seamless – Can be applied to complex shapes to form a seamless and highly durable water proofing coating.

Adhesion – Adheres firmly to most of building surfaces including concrete, brick etc. both horizontal and vertical surfaces.

Water based – Easy cleaning of tools and brushes by water.

Easy to apply – Suitable consistency for easy application by brush, roller or squeegee.

Packaging

1, 5, 10 & 20 Ltrs

Also Read: Dr. Fixit Pidiproof LW+ Integral Liquid Waterproofing Compound for Concrete and Plaster

Method of Application – Dr. Fixit Roofseal Waterproofing

Surface Preparation

- Clean the entire roof with Pressure water jet to remove the unwanted dust, loose material, oil, or any other material which may impair adhesion of the material. Surface must be cleaned and dried properly so that any cracks on the substrate can be visible. Concrete substrate to be cleaned up to exposed sound concrete cover, remove dust, laitance etc , which may impair adhesion of the material.

- Mark the area having cracks.

- All surface cracks up to 1-2 mm wide should be filled with Dr. Fixit Roofseal using a brush. Add a coat on the slab on both sides of the crack, up to a distance of 100 mm around it. Cracks more than 1-2 mm should be widen by making V-groove and repaired with PMM (Polymer Modified Mortar)using Dr. Fixit Pidicrete URP 10% by weight of cement.

- All joints of vertical up stand should have 50 x 50 mm angle fillets prepared with sand –cement mortar; mixed with Dr. Fixit Pidicrete URP.

- Curing to be provided to the angle fillets and repaired surface as per standard methodology before application of coating.

- Apply one coat of Dr. Fixit Roofseal on the angle fillet area and put 45 gsm Glass fiber mesh 200 mm on both the sides of the fillet to make the junction and corner’s receptacle to movements. The same treatment should be carried out for Drain outlets.

Priming

- Primer is required only for high absorbent surface such as light weight concrete. Primer recommended to be used is Dr. Fixit Primeseal.

Application – Dr. Fixit Roofseal Waterproofing

- Sprinkle some water over the roof just before application of Dr. Fixit Roofseal.

- Apply 2 coats Dr. Fixit Roofseal at 0.75 ltrs / m2/ coat, at an interval of 12 hrs between the coats and allow drying completely. A layer of suitable reinforcing fabric (Glass fiber) should be incorporated within the first coat.

- 2nd coat to be applied in a direction perpendicular to the 1st coat.

Water ponding test

- After full drying of second coat for at least 72 hrs, a water ponding test can be performed by filling water on the terrace by carefully blocking all the down take drain outlets without damaging the coating. The test shall be carried out for 48 hrs by filling water up to 50 mm level. Observe for leakages if any and then remove the water and allow the coating to dry completely.

Coating overlay with brickbat coba, china mosaic or mud phaska

- After the coating is dried lay sand and cement mortar (Plaster) prepared with Dr. Fixit Pidiproof LW+ covering the complete exposed flat area including up stand areas for the protection of applied coating.

- Upon completion of the plaster and proper curing/drying, further finishing activities such as mud phaska brickbat coba china mosaic & tile fixing can be carried out with proper slope towards the drain water outlet.

Protection concrete screed – Alternative

- Spread 100 gsm/m2 geotextile over cured Dr. Fixit Roofseal as separation layer, before a concrete screed is laid. Protect the coating with a concrete screed in M 20 grade. The protective screed of 40-50 mm (minimum) thickness maintaining an average slope of 1:100 towards the drain outlets for effective and efficient draining of water.

- The composition of screed should be 1:1.5:3 i.e. Cement: Sand: Aggregate with aggregate size 20 mm down. The screed should also have poly propylene fibre 12 mm length & should not be less than 150 gram per 50 kg bag of cement.

- Sprinkle the fibre in site mixer with little water. Keep rotating and add aggregate, sand, cement and balance water. Mix it for a few minutes. In case of manual mixing, for best results mix half the fibre in a bucket of water, stir well and mix in concrete. Likewise add balance fibre.

- The addition of fibre will contribute in controlling cracking caused by volume change (Expansion & Contraction). Helps in increasing flexural strength.

- Angle fillet to be provided while screed application using polymer modified mortar.

- After the application of screed, provide control joints along the length and breadth of entire screed area.

- The joint can be provided by using a saw cutting machine attached with a 3 mm blade within 18-24 hrs of

- application of screed. The panel size for providing joints should be 3.25 m x 3.25 m.

- 28-30 days later, these joints can be filled with a suitable elastomeric sealant.

Optional – During surface preparation an important thing is the fitting of drain outlets. Dr. Fixit Roofix Drain is designed to prevent the possible leakages from this most critical area. Roofix Drain is aligned with the drain down take pipes. The drain is fitted by carefully aligning and fitting using Dr. Fixit Pidicrete URP modified mortar. During the fitting care is taken to provide a catchment area at the drain area aligned with the slope provided in the screed. Dr. Fixit Roofseal coating is done along the fitting area as an additional coating before proceeding for final coating.

Precautions & Limitations – Dr. Fixit Roofseal Waterproofing

1. Careful supervision during application is needed, particularly in ensuring proper curing of concrete and

consistent thickness.

2. Apply Dr. Fixit Roofseal directly.

3. Always protect the coating with proper and appropriate protection.

4. Do not apply Dr. Fixit Roofseal directly in open sunlight when temperature is higher than 35 degree C.

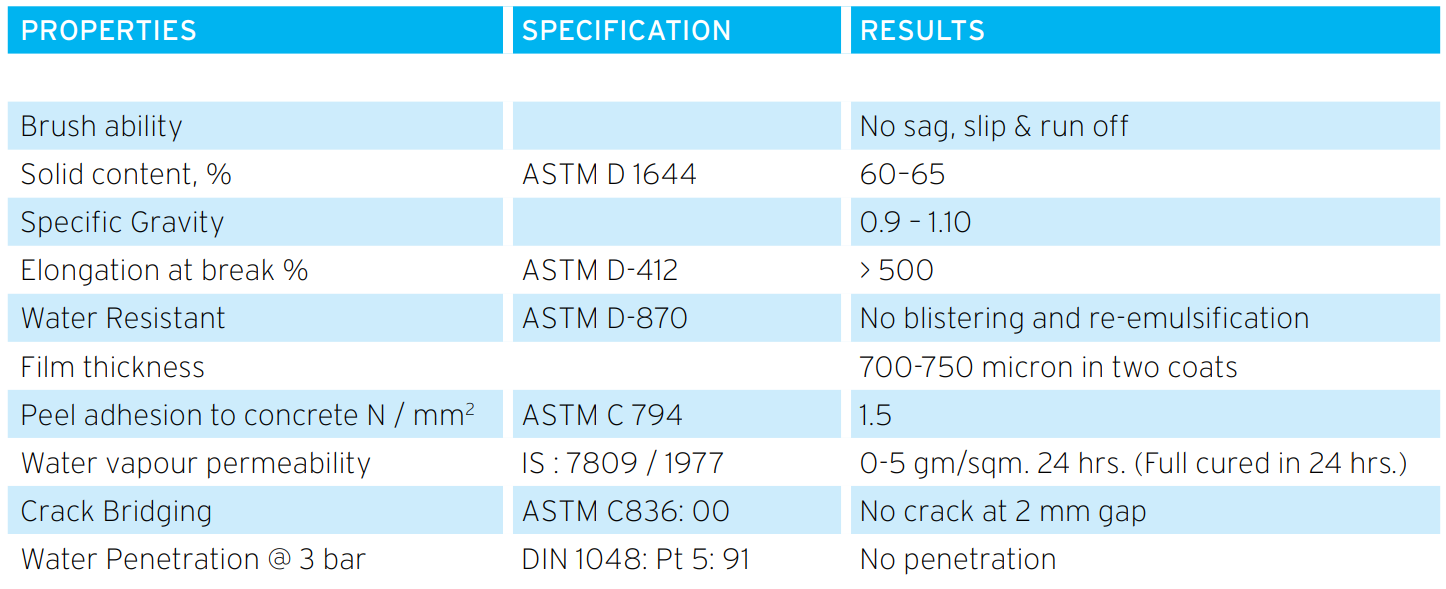

Technical Information – Dr. Fixit Roofseal Waterproofing

Theoretical Coverage – Dr. Fixit Roofseal Waterproofing

0.75 Ltrs/ m2 / coat

NOTE – Coverage may vary depending upon the texture and porosity of the surface.

Shelf Life

Shelf life is 12 months from the date of manufacturing in unopened condition. Store in cool and dry place. Keep away from direct sun light.

Health & Safety

PPE: During application wear protective clothing, gloves and eye goggles during application. Avoid product to contact eyes and skin.

Skin Contact: Wash immediately with plenty of clean water, use kerosene or mineral turpentine when the

product has dried.

Eye contact: In the event of eye contact splash plenty of clean water immediately and seek medical advice.