Handrails should be kept in top condition at all times. Ensuring their good shape is essential in ensuring everyone’s safety at the workplace. To help you in maintaining handrail safety, we will enlist twelve hazards that you should avoid at all times. Avoiding the occurrence of the following hazards by regular monitoring, observation, evaluation, and proper planning will make your workplace safe and secure for all workers.

Hazard #1: Delay in repair and maintenance

All handrails should immediately be repaired when issues and concerns arise. A delay in repair can cause confusion and expose workers to broken handrails that can still be used and cause falls and accidents. All areas with broken handrails should be off-limits. No workspace with handrails that need to be repaired should be accessible to workers.

Hazard #2: Sudden modification and extension in height of handrails

No sudden and unplanned modification of handrails should take place. All should be scheduled in advance and all concerned personnel and workers must be duly briefed and trained. Workers and personnel are used to their regular workflow and such a sudden change can cause a mistaken belief in safety when such is not the case.

Hazard #3: Inspection by incompetent personnel

A handrail safety inspection should only be done by an expert and certified personnel. Personnel with no idea as to what to look for and what to consider should never be assigned to do a handrail safety inspection. Inspection should be done regularly and consistently. Proper records of the inspection schedule should be kept. It should duly enlist all past and scheduled handrail safety inspections.

Hazard #4: Unspecified repairs by incompetent workers

All repairs should be duly specified in a clear and direct manner. Repairs should be properly described, measured, and evaluated. A general description of a repair is not enough. A proper description of a repair should involve the following: what was the issue, how it was solved, what was changed or maintained, and how it was tested safe for operation. Should there be a need for replacement, such need must be clearly enlisted and described. A general description like this: Sandvik replacement parts, will not suffice.

Hazard #5: No placed protocols for prevention of drowning

All workplaces should have a solid protocol for the prevention of drowning in the workplace. This should be done not only in workplaces by the sea but in areas where workers can be exposed to big bodies of water or liquid placed in a container. The placement of proper protocol will ensure that personnel and workers are duly briefed and trained for effective accident prevention.

Hazard #6: No placed protocols for prevention of exposure to harmful atmospheres

Solid protocols should also be in place for the prevention of exposure to harmful atmospheres. Exposure can easily occur in instances where damaged or broken handrails are used. To prevent this, proper planning that considers possible atmosphere exposure should take place. This is highly imperative in workplaces that deal with harmful substances and items that can instantly damage a person’s health.

Hazard #7: No placed protocols for prevention of exposure to hazardous materials

Workplaces that deal with hazardous materials should have a strict protocol in place to prevent personnel and workers from accidents that can occur should handrails be broken or damaged. Companies in such industries should have an extensive list of hazardous materials that workers can be exposed to. All workers must be duly briefed and properly trained to prevent such exposure.

Hazard #8: Rushed handrail inspection

Handrail safety inspections should be deployed in a serious, meticulous, and careful manner. Every single aspect and factor should be checked to ensure that all handrails are safe for use. No inspection should ever be rushed on, done in a hasty manner. All actions must be intentional and clear in securing everyone’s safety.

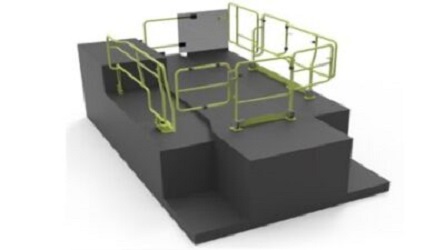

Hazard #9: Failure of competent persons to design specified handrails for on-site needs

It is extremely dangerous for any person to be working in a field with handrails that were not specifically designed for unique conditions. Such is highly risky as no task can ever be definitely safe and secured. To avoid this, companies must endeavor to place customized handrails in their workspaces.

Hazard #10: Failure of competent persons to inspect damaged handrails prior to repair

Handrails require particular care. When damaged, no repair should be done in an instant without prior inspection. This is to ensure that all damages are clearly seen and directly addressed. Failing to proceed with a dedicated inspection before actual repair can lead to further damage. Such inspection should also be limited to competent experts.

Hazard #11: Mistaken concept of handrails

Handrails should be seen as separate safety equipment and not a mere part of an object. A clear understanding of this concept will make it easier for any company to secure personnel safety. Handrails should be maintained as separate safety equipment that needs a regular meticulous inspection done by experts. Such maintenance is entirely unique and separate from other workplace items.

Hazard #12: No prior personnel briefing and training

All personnel and workers must be duly briefed and trained when it comes to handrail safety. They should all be duly aware of all the dangers and risks involved in their work. They should all know when it is already risky to be using a handrail. They should all know how to proceed when they determine that a handrail is no longer safe.