Segregation of Concrete – Types Causes and Prevention

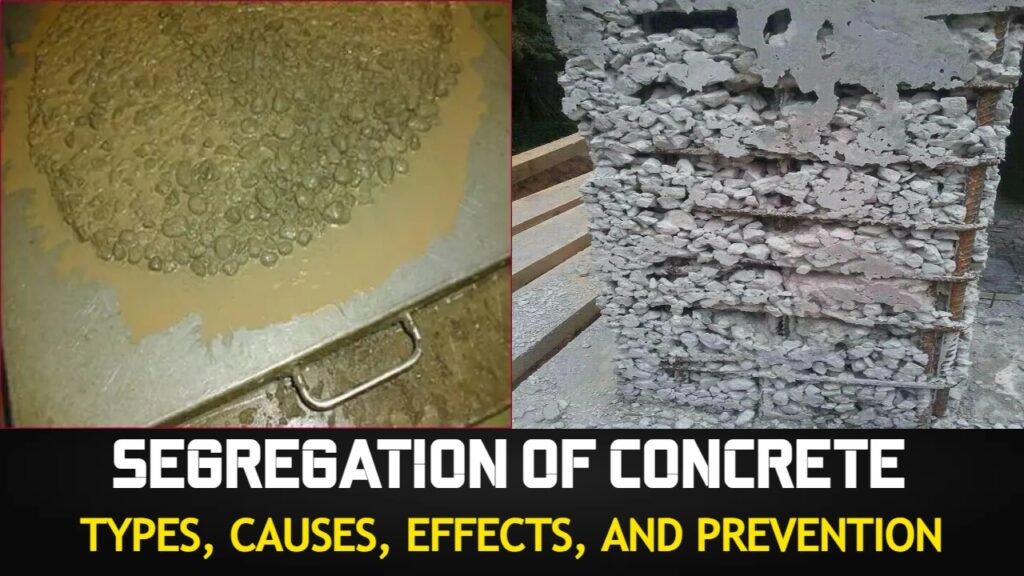

Segregation of concrete can be defined as the separation of the constituent materials of concrete. Good concrete is one in which all the ingredients are properly distributed to make a homogeneous mixture. If a sample of concrete exhibits a tendency for separation of say, coarse aggregate from the rest of the ingredients, then, that sample is said to be showing the tendency for segregation. Such concrete is not only going to be weak, but lack of homogeneity is also going to induce all undesirable properties in the hardened concrete.

There are considerable differences in the sizes and specific gravity of the constituent ingredients of concrete. Therefore, It is natural that the materials show a tendency to fall apart.

ALSO READ

- Factors Affecting Workabilty Of Concrete – Concrete Technology

- Workability of Concrete in Civil Construction

- What is the Purpose of Concrete Mix Design?

- Self Compacting Concrete (SCC)

- Concrete – Definition Properties and Classification

Types of Segregation of Concrete

Segregation may be broadly classified into three types.

Firstly, the coarse aggregate separating out or settling down from the rest of the matrix.

Secondly, the paste or matrix separating away from the coarse aggregate.

Thirdly, water separating out from the rest of the material being a material of lowest Specific Gravity.

A well-made concrete, taking into consideration various parameters such as grading, size, shape and surface texture of aggregate with the optimum quantity of water makes a cohesive mix. Such concrete will not exhibit any tendency for segregation.

The Cohesive and fatty characteristics of the matrix does not allow the aggregate to fall apart, at the same time, the matrix itself is sufficiently contained by the aggregate. Similarly, water also does not find it easy to move out freely from the rest of the ingredients.

- Measure Horizontal Distance Using AutoLevel

- Bulking OF Fine Aggregates

- Concrete Cube Samples Taken for Different Volume

- Grades of Concrete as per IS 456 : 2000

- What is 1.54 in Concrete

Causes for Segregation of Concrete

The badly proportioned mix where sufficient matrix is not there to bind and contain the aggregates.

Insufficiently mixed concrete with excess water content shows a higher tendency for segregation.

Dropping of concrete from heights as in the case of placing concrete in column concreting will result in segregation.

When concrete is discharged from a bad design mixture, or from a mixture with worn out blades, concrete shows a tendency for segregation.

Prevention of Segregation of Concrete

The vibration of concrete is one of the important methods of compaction. It should be remembered that only a comparatively dry mix should be vibrated. It too wet a mix is excessively vibrated, it is likely that the concrete gets segregated. It should also be remembered that vibration is continued just for the required time for optimum results. If the vibration is continued for a long time, particularly, in too wet a mix, it is likely to result in the segregation of concrete due to the settlement of coarse aggregate in a matrix.

In recent times, we use concrete with a high slump, particularly in RMC. The slump value required at the batching point maybe in the order of 150 mm and at the pumping point the slum may be around 100 mm. At but these points cubes are cast. One has to take care to compact the cube mould with these high slump concrete. It sufficient care and understanding of concrete are not exercised, the concrete in the cube mould may get segregated and show low strength. Similarly, care must be taken in the compaction of such concrete in actual structures to avoid segregation.

While finishing concrete floors or pavement, with a view to achieving a smooth surface, masons are likely to work too much with the trowel, float or tamping rule immediately on placing concrete. This immediate working on the concrete on placing, without any time interval, is likely to press the coarse aggregate down, which results in the movement of an excess of matrix or paste to the surface. Segregation caused on this account impairs the homogeneity and serviceability of concrete. The excess mortar at the top causes plastic shrinkage cracks.

From the foregoing discussion, it can be gathered that the tendency for segregation can be remedied by correctly proportioning the mix, by proper handling, transporting, placing, compacting and finishing. At any stage, if segregation is observed, remixing for a short time would make the concrete again homogeneous.

As mentioned earlier, a cohesive mix would reduce the tendency for segregation. For this reason, the use of certain workability agents and pozzolanic materials greatly helps in reducing segregation. The use of air-entraining agent appreciably reduces segregation. In the design of self-compacting concrete mix, one of the three characteristics aimed at is the resistance to segregation. The parameter such as water/powder ratio, total powder cement, sand content etc is adapted mainly to resist segregation in self-compacting concrete.

Segregation is difficult to measure quantitatively, but it can be easily observed at the time of concreting operation. The pattern of subsidence of concrete in a slump test or the pattern of spread in the flow test gives a fair idea of the quality of concrete with respect to segregation.

You can also follow me on Instagram, Telegram and Facebook page. Because many small things, which are very important from interview point of view, it is not possible to put here, I put all that on Instagram, Telegram and Facebook page. You can take it from there. You will find the links of all social media below.

INSTAGRAM | TELEGRAM | FACEBOOK PAGE