Steel is a key building element when building your own home and it significantly affects construction costs. So, we must be aware of the current steel price per kilogram.

Steel is one of the most expensive and often utilized building materials since its cost is considerable in comparison to other materials. Without steel, no building project can be finished. Concrete is strong in compression but weak in tension, thus steel bar reinforcing is utilized to give the concrete its tensile strength.

As per India Standard Specification, steel is provided as rolled steel bars in a range of diameters.

The list of steel bar diameters most often used for building projects in India is shown below.

8mm, 10mm, 12mm, 16mm, 20mm, 25mm, 32mm, and 40mm

You may get steel bars directly from steel producers if you need a large quantity of steel, or you can buy them through local material providers.

Contents

Understanding Steel Pricing

Tor Steel is essential to several sectors, including infrastructure development, industry, and building. There are a number of variables that affect steel’s pricing, and each has a big impact on how much it is worth in the market. You may obtain a competitive edge when sourcing and pricing steel for your projects by being aware of these elements.

Supply and Demand Dynamics

The price of steel is significantly influenced by the law of supply and demand. Prices for steel often increase when demand outpaces supply and vice versa. Economic expansion, building activity, and industrial output all have a direct impact on steel demand. Steel prices are influenced by supply-side elements such as the availability of raw materials, production capacity, and trade policies.

Raw Material Costs

Iron ore, coal, and scrap metal are only a few of the raw materials used in the making of steel. The total cost of making steel is considerably impacted by changes in these commodities’ pricing. Changes in mining practices, geopolitical situations, and environmental restrictions can cause raw material cost volatility, which in turn can have an impact on steel pricing.

Energy Prices

Energy costs, especially those related to fuel and electricity, have a big impact on how much steel is produced. Significant quantities of energy are used in the production process at steel mills. As a result, changes in energy prices that are caused by things like fuel supply, geopolitical unrest, and environmental regulations may have an effect on steel pricing.

Market Speculation and Global Trade

Market speculation and the dynamics of international commerce may have an impact on steel pricing. Short-term price variations are a common result of wagers placed by speculators, investors, and traders on steel prices in the future. The worldwide supply and demand balance may be impacted by trade policies, taxes, and import/export laws, which in turn can affect steel prices.

Also Read: MS Angle Weight Chart PDF: Calculate MS Angle Weight for On-Site Billing in 3 Steps

Steel Price Per Kg Today 2023

The current TMT Steel Price Per Kg is as follows:

Steel Cost Per Kg For Grade Fe 500

| Brands | 8 mm | 10 mm | 12 mm | 16 mm | 20 mm | 25 mm |

| TATA Tiscon | 73.30 | 73.55 | 73.53 | 73.74 | 73.91 | 69.49 |

| JSW Steel | 732.27 | 70.16 | 75.19 | 75.19 | 75.19 | 75.19 |

| Kamdhenu | 58.60 | 57.50 | 57.50 | 57.50 | 57.50 | 57.60 |

| Sail | 79.30 | 79.30 | 79.30 | 79.30 | 78.30 | 78.30 |

| Vizag | 66.69 | 66.69 | 67.87 | 67.87 | 67.87 | 67.87 |

| Primegold | 59.60 | 589.56 | 60.75 | 60.75 | 60.75 | 60.75 |

| A1 Gold | 63.65 | 63.58 | 63.68 | 63.68 | 64.68 | 64.68 |

| Ultra TMT | 65.54 | 65.54 | 64.24 | 64.24 | 64.24 | 65.54 |

| Meenakshi | 54.80 | 55.26 | 52.26 | 52.26 | 53.26 | 53.80 |

| Tirupati TMT | 60.50 | 60.50 | 60.00 | 60.00 | 60.00 | 59.95 |

| Birla TMT | 74.00 | 75.80 | 75.80 | 75.80 | 75.80 | 75.80 |

Steel Cost Per Kg For Grade Fe 415

| Brands | 8 mm | 10 mm | 12 mm | 16 mm | 20 mm | 25 mm |

| TATA Tiscon | 68.30 | 68.55 | 68.53 | 68.74 | 69.91 | 69.49 |

| JSW Steel | 72.27 | 72.16 | 70.19 | 70.19 | 72.19 | 72.19 |

| Kamdhenu | 55.60 | 55.50 | 57.50 | 57.50 | 57.50 | 57.60 |

| Sail | 78.30 | 78.30 | 87.30 | 81.30 | 80.30 | 80.30 |

| Vizag | 63.69 | 63.69 | 63.87 | 66.87 | 66.87 | 66.87 |

| Primegold | 55.60 | 55.56 | 60.75 | 60.75 | 60.75 | 60.75 |

| A1 Gold | 57.65 | 57.58 | 57.68 | 57.68 | 57.68 | 57.68 |

| Ultra TMT | 62.54 | 64.54 | 63.24 | 63.24 | 63.24 | 64.54 |

| Meenakshi | 55.80 | 52.26 | 52.26 | 52.26 | 52.26 | 52.80 |

| Tirupati TMT | 58.50 | 58.50 | 58.00 | 58.00 | 58.00 | 58.95 |

| Birla TMT | 69.00 | 69.80 | 69.80 | 70.80 | 70.80 | 70.80 |

Steel Cost Per Kg For Grade Fe 250

| Brands | 8 mm | 10 mm | 12 mm | 16 mm | 20 mm | 25 mm |

| TATA Tiscon | 65.30 | 65.55 | 65.53 | 67.74 | 70.91 | 69.49 |

| JSW Steel | 65.27 | 65.16 | 65.19 | 66.19 | 66.19 | 66.19 |

| Kamdhenu | 55.60 | 55.50 | 55.50 | 57.50 | 57.50 | 57.60 |

| Sail | 68.30 | 68.30 | 68.30 | 69.30 | 69.30 | 69.30 |

| Vizag | 62.69 | 62.69 | 62.87 | 66.87 | 66.87 | 66.87 |

| Primegold | 56.60 | 56.56 | 56.75 | 58.75 | 58.75 | 58.75 |

| A1 Gold | 58.65 | 58.58 | 58.68 | 59.68 | 59.68 | 59.68 |

| Ultra TMT | 61.54 | 61.54 | 61.24 | 62.24 | 62.24 | 62.54 |

| Meenakshi | 50.80 | 50.26 | 50.26 | 51.26 | 51.26 | 51.80 |

| Tirupati TMT | 59.50 | 59.50 | 59.00 | 59.00 | 59.00 | 59.95 |

| Birla TMT | 62.00 | 62.80 | 62.80 | 63.80 | 63.80 | 63.80 |

Prices for various steel products

| Steel Products | Cost of steel per Kg | Cost of steel per tonne | Cost of steel per pound |

| Steel Rebar | 46.5 | 46500 | 102.51 |

| Wire Rod | 43.3 | 45300 | 95.90 |

| Sections and beams | 44.8 | 44800 | 98.76 |

| Merchant bar | 47.2 | 47200 | 104.05 |

| Hot rolled coil | 65.5 | 65500 | 144.40 |

| Hot rolled plate | 64 | 64000 | 141.09 |

| Cold rolled coil | 76 | 76000 | 167.55 |

| Hot dipped Galvanised coil | 84 | 84000 | 185.18 |

Also Read: Top 250 Civil Engineering Interview QnA : PDF Download

Factors Affecting Regional Steel Price Variations

Numerous variables that affect the price of steel in various regions might be the cause of regional variances in steel prices. For accurate cost assessment and successful budget planning, it is essential to comprehend these aspects. The following are the main factors that affect regional variations in steel prices:

Transportation Costs: A number of variables, including distance, method of transportation, and infrastructure quality, can have a major impact on the price of carrying steel from manufacturing facilities to end users. Higher transportation expenses may be incurred in remote or landlocked places, which may affect the ultimate price of steel in those areas.

Local Taxes and Duties: Steel goods are subject to a variety of taxes, tariffs, and levies depending on the location. In a particular area, these additional expenses have a direct impact on the final price of steel. These elements must be taken into account when comparing the price of steel per kilogram across various marketplaces.

Currency Exchange Rates: The price of imported steel may alter as a result of fluctuations in currency exchange rates. The price of imported steel rises as the local currency depreciates versus the currencies of nations that produce steel. On the other hand, reduced steel prices may arise from a stronger local currency.

Regional Demand and Supply: The dynamics of supply and demand in a particular area have a big impact on steel pricing. The regional demand for steel is influenced by variables like regional economic circumstances, industrial development, construction activity, and infrastructure growth. Regional steel prices are also influenced by the supply side, which is impacted by the availability of local steel production and the reliance on imports.

Regulatory Environment: Different regulatory structures and regulations that impact the steel sector may exist in each location. Government policies, trade agreements, labor laws, and environmental restrictions all have an effect on the price of steel in a given location.

Market Competition: Steel prices may vary depending on the degree of competition in a particular area. Competitive pricing methods to increase market share may result from increased rivalry among steel suppliers. On the other hand, fewer competitors can raise prices since there are fewer alternatives for consumers.

For companies and individuals working in steel procurement, building projects, and other connected sectors, it is crucial to comprehend these elements and how they affect regional steel costs. Market participants may make informed decisions, reduce costs, and efficiently manage their steel-related operations by taking these geographical variances into account.

Please keep in mind that this list is not complete, and additional region-specific factors might potentially affect steel prices.

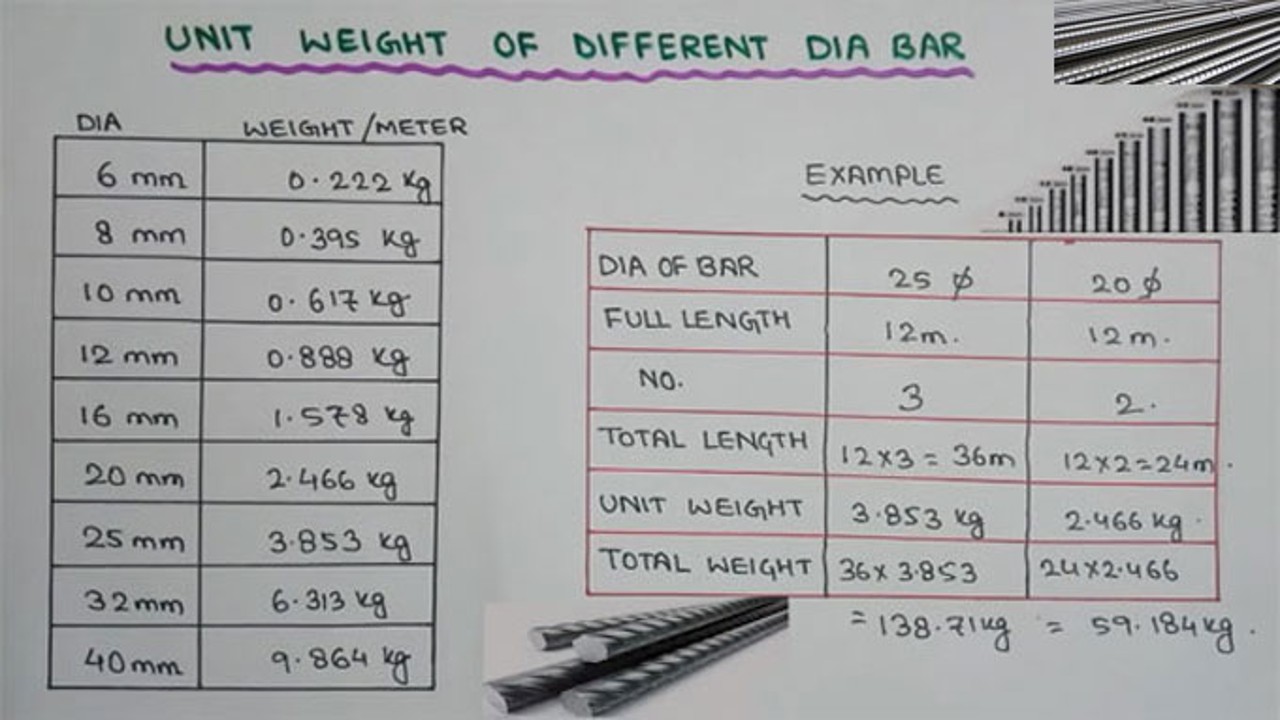

Weight of Steel Bars of Various Diameters

The following table shows the unit weight of steel bars,

| Dia of Steel Bar | Length | Unit Weight |

|---|---|---|

| 8 mm | 1 m | 0.395 kg/m |

| 10 mm | 1 m | 0.610 kg/m |

| 12 mm | 1 m | 0.89 kg/m |

| 16 mm | 1 m | 1.58 kg/m |

| 20 mm | 1 m | 2.46 kg/m |

| 25 mm | 1 m | 3.87 kg/m |

| 32 mm | 1 m | 6.32 kg/m |

| 40 mm | 1 m | 9.87 kg/m |

Also Read: TMT Steel Bar Weight Calculation At Construction Site in 3 Easy Steps

India’s Steel Bars In Various Grades

Steel bars, usually referred to as reinforcement bars or rebars, are extremely important to the Indian construction sector. These bars provide reinforced concrete constructions with their structural integrity and strength. On the Indian market, there are many grades of steel bars, each created to satisfy particular needs and criteria. Here are some of the grades of steel bars that are most often used in India:

Mild Steel Bars (M.S. Bars): The most popular kind of steel bars used in building projects are mild steel bars, often known as plain carbon steel bars. They contain carbon in the range of 0.15% to 0.25%. Mild steel bars are reasonably priced, have good weldability, and have good ductility. They are mostly utilized for modest to medium-sized projects and ordinary buildings.

Fe415 Grade Bars: In India, TMT (Thermo-Mechanically Treated) bars made of Fe415 grade steel are commonly utilized. Iron is denoted by the “Fe” prefix, while “415” is the minimum yield strength of the bars in megapascals (MPa). With a yield strength of 415 MPa OR N/mm2, Fe415 bars are appropriate for a range of construction constructions, including residential buildings, bridges, and commercial projects.

Fe500 Grade Bars: Another common variety of TMT bars used in India is Fe500 grade steel bars. Compared to Fe415 bars, they have a greater yield strength of 500 MPa OR N/mm2, suggesting improved structural strength. Heavy-duty constructions with increased load-bearing capability, such as high-rise buildings, industrial structures, and infrastructure projects, frequently employ Fe500 bars.

Fe550 Grade Bars: Fe550 grade steel bars are stronger than Fe500 bars, with a yield strength of 550 MPa OR N/mm2. These bars are frequently employed in construction projects that demand increased sturdiness and durability, such as bridges, flyovers, and high-rise buildings that must withstand heavy weights.

Fe600 Grade Bars: With a minimum strength of 600 MPa OR N/mm2, Fe600 grade steel bars have the greatest yield strength among the widely accessible TMT bars in India. These bars are used in specialized applications, such as in pre-stressed concrete components, big industrial structures, and infrastructure projects with strict load-bearing specifications.

The aforementioned grades are generally accepted in the Indian construction sector and are based on the Bureau of Indian Standards (BIS) criteria, it is crucial to note. However, depending on the requirements of a particular project, alternative grades, and customized tor steel bars can be available.

It is crucial to take into account aspects like structural design, load requirements, durability, and corrosion resistance while choosing steel bars for construction. Choosing the right grade of steel bars for a particular building project may be made easier by consulting with structural engineers and following to applicable regulations and rules.

Construction experts may choose the steel bars that best fit their project demands by having a thorough grasp of the various grades of tor steel bars that are offered in India. This will ensure structural integrity and long-term durability.

List of India’s Top Steel Brands 2023

Tor Steel of various grades was produced by several businesses. Below is a list and explanation of some of India’s top tor steel manufacturers:

- Tata Steel

- JSW Steel Ltd.

- Steel Authority of India Limited (SAIL)

- Essar Steel Ltd.

- Shyam Steel Industries Ltd.

- Jindal Steel and Power Ltd.

- VISA Steel

- SRMB Steel

- Electosteel

- Mesco Steel

- Kamdhenu Steel

Conclusion

In conclusion, it is critical for everybody working in the steel sector to understand the variables that affect the price of steel per kg. You may manage the steel market more successfully by taking factors into accounts such as supply and demand dynamics, raw material costs, energy prices, and international commerce. You may also make wise judgments when buying steel by being aware of geographical variances and visualizing pricing patterns.

Keep in mind that the price of steel is influenced by a variety of outside variables, therefore it is crucial to monitor the market. By utilizing this thorough guide, you are now armed with insightful knowledge that may help you outperform rivals and make more sensible choices about steel costs per kg.

Frequently Asked Questions – FAQs

What is Tor steel?

TMT (Thermo-Mechanically Treated) steel, commonly referred to as tor steel, is a form of reinforcing bar that is frequently used in the building sector. It is renowned for its improved tensile strength, ductility, and corrosion resistance.

What are the advantages of using Tor steel in construction?

Tor steel has several benefits for building, such as strong tensile strength, greater concrete bond strength, improved resistance to seismic stresses, and improved durability. It enhances the safety and durability of reinforced concrete structures and offers structural integrity.

What are the different grades of Tor steel available?

There are several grades of tor steel, including Fe415, Fe500, Fe550, and Fe600. These grades list the steel bars’ relative strengths and load-bearing capabilities as well as their minimum yield strength in megapascals (MPa).

How is Tor steel different from ordinary steel bars?

After hot rolling, Tor steel goes through a specialized thermo-mechanical treatment procedure that includes controlled cooling. When compared to regular steel bars, this technique gives the steel improved mechanical qualities, such as enhanced strength and ductility, making it more appropriate for building uses.

Is Tor steel more expensive than ordinary steel bars?

Due to its superior qualities and the additional processing required during its manufacturing, tor steel is often somewhat more expensive than regular steel bars. However, the structural advantages and long-term advantages it provides surpass the minor increase in price.

Can Tor steel be welded?

Yes, Tor steel may be welded with the right electrodes and welding procedures. To preserve the strength and integrity of the welded connections, it is crucial to adhere to the suggested welding processes.

How is the quality of Tor steel ensured?

Adherence to pertinent standards, such as the Bureau of Indian Standards (BIS) norms, ensures the quality of Tor steel. Reputable manufacturers put their goods through extensive testing to make sure they meet quality requirements and give clients the right paperwork.

Can Tor steel be used in coastal areas?

Yes, Tor steel is appropriate for usage in coastal regions and other places where there is a high likelihood of dampness or exposure to seawater. It is perfect for these circumstances because of its high corrosion resistance qualities.

What is the lifespan of Tor steel in concrete structures?

Tor steel may last as long as the concrete structure’s design life when applied appropriately and in typical circumstances. The structural strength and corrosion resistance of reinforced concrete contributes to its toughness and lifespan.

Can Tor steel be recycled?

Yes, Tor steel may be recycled. Tor steel may be recycled once it reaches the end of its useful life and utilized to create new steel products, helping to promote sustainability and resource preservation.

Please note that the answers provided are general and may vary based on specific circumstances, regional standards, and industry practices. It is advisable to consult with structural engineers and adhere to local regulations and codes when using Tor steel in construction projects.