MS Angle Weight Chart: For planning and invoicing purposes, proper material estimation is essential in building projects. Calculating the unit weight is crucial in establishing the amount of materials needed when working with M.S (Mild Steel) angles. You can follow the instructions in this article to determine the M.S. angle unit weight for invoicing reasons. We’ll talk about the value of an M.S Angle Weight Chart, how to calculate it, show you an example calculation, and then discuss how important it is for appropriate invoicing.

Contents

- 1 What is MS Angle?

- 2 What is an MS Angle Weight Chart?

- 3 Importance of MS Angle Weight Chart

- 4 Calculation Methodology

- 5 MS Angle Weight Chart PDF

- 6 MS Angle Weight Calculation for Billing at Site

- 7 Watch Reference Video

- 8 Conclusion

- 9 Frequently Asked Questions – FAQs

- 9.1 What is an Mild Steel angle weight chart used for?

- 9.2 How is the unit weight of M.S. angle calculated?

- 9.3 Why is accurate material estimation important in billing?

- 9.4 How does calculating the unit weight help in resource utilization?

- 9.5 Can the unit weight of Mild Steel angle vary?

- 9.6 Is the unit weight of Mild Steel angle the same as its actual weight?

- 9.7 How does accurate billing benefit construction projects?

- 9.8 Can an M.S angle weight chart be specific to a manufacturer?

- 9.9 Is an MS angle weight chart applicable to other types of steel angles?

- 9.10 Why is it important to follow the calculation methodology?

What is MS Angle?

MS Angle is a form of steel product with an L-shaped cross-section that is also referred to as Mild Steel Angle or Structural Steel Angle. Due to its strength and adaptability, it is frequently utilised in structural, manufacturing, and construction applications. MS angles are frequently utilised to give constructions like buildings, bridges, towers, and frames support, stability, and load-bearing capability.

MS angles come in a variety of shapes and sizes, usually identified by their width, thickness, and length. While the thickness relates to the thickness of the angle’s legs, the width describes the breadth of the angle’s one side. The length might change depending on the needs of the project and is often trimmed to precise proportions during manufacture.

Mild steel, a low-carbon steel with high weldability and formability, is used to make these angles. MS angles are a cost-effective option for structural applications since mild steel has good mechanical qualities and is noted for being inexpensive.

Steel billets or ingots that have been heated to high temperatures and formed in rolling mills are commonly used to create MS angles. This production procedure guarantees uniform mechanical characteristics and dimensions across various MS angle sizes.

MS angles are frequently employed in construction to build connections, supports, and frames. To create different structural parts like beams, columns, trusses, and bracing members, they can be bolted, welded, or otherwise joined together. Due of MS angles’ adaptability, buildings may be designed and built to meet a variety of load requirements and architectural specifications.

Small angles used in lightweight applications to bigger, heavier angles used in heavy-duty construction projects—MS angles come in a broad variety of diameters. According to their size and thickness, MS angles have different weights, thus it’s crucial to refer to weight tables or manufacturer specifications for precise weight information.

Overall, MS angles are crucial parts of the building business since they give a variety of constructions strength, stability, and diversity. They are a well-liked option for both builders and engineers as well as architects because to its frequent use, affordability, and simplicity of production.

What is an MS Angle Weight Chart?

A reference tool that offers details on the weight of MS angles of various sizes is an MS angle weight chart. It generally lists the width, thickness, and weight per unit length of the angles, which is often expressed in kilogrammes per metre (kg/m). The MS Angle Weight Chart is a useful tool for structural design, load capacity estimate, and material estimation, enabling accurate calculations in construction projects (MS Angle Weight Chart)

Importance of MS Angle Weight Chart

Accurate Material Estimation: A MS angle weight chart makes it easier to estimate material accurately for invoicing. Construction experts can determine the overall weight of M.S. angles needed for a project by using the weight table. This promotes accurate material acquisition, guards against excess or shortages, and ensures cost-effective invoicing.

Optimal Resource Utilization: An MS angle weight chart is useful for maximising resource use. Construction experts may establish how many M.S. angles are required by precisely measuring the unit weight, minimising waste and cutting down on needless costs. Cost containment and effective project management are the results of this.

Billing Accuracy: Billing accuracy is ensured by calculating the unit weight of M.S. angles. Construction experts may appropriately charge clients depending on the materials used by weighing each angle used in the project. This openness fosters confidence and upholds an equitable charging system.

Also Read: Top 250 Civil Engineering Interview QnA : PDF Download

Calculation Methodology

The method below can be used to get the unit weight of M.S. angles:

- Get the width (W) and thickness (T) measurements of the M.S. angle.

- Apply the following equation to determine the cross-sectional area (A) of the angle: A = (W – T) T.

- By multiplying the cross-sectional area by density of steel (K), one may get the unit weight (UW) per unit length. Depending on the M.S. angle density, which is normally approximately 7850 kg/m3, the constant factor may change.UW = A × K.

Example Calculation:

Let’s take a look at an M.S. angle with the following measurements: W = 50 mm; T = 5 mm.

- Cross-sectional area (A) = (50 – 5) × 5 = 225 mm²

- Converting the cross-sectional area to square meters (m²), A = 225 × 10⁻⁶ m²

- Assuming the density of steel (K) as 7850 kg/m³:

- Unit Weight (UW) = A × K = 225 × 10⁻⁶ × 7850 kg/m = 1.76 kg/m.

Also Read: How to Convert Sand from CFT (Cubic Feet) to KG (Kilograms)

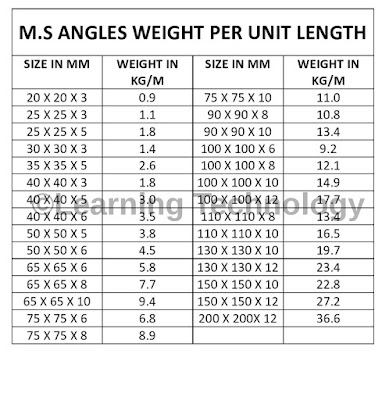

MS Angle Weight Chart PDF

Please note that these weights are approximations and might change based on the brand and kind of mild steel utilised. The manufacturer’s specs should always be consulted for precise weight information – MS Angle Weight Chart

MS Angle Weight Calculation for Billing at Site

For billing reasons, the unit weight of M.S. angle determined using the aforementioned methods, in this case 1.76 kg/m, is applied. The weight of each metre of M.S. angle utilised in the building project is represented by it.

MS Angles are L-shaped structural steel defined by dimension of sides & thickness.

For Example 20 x 20 x 3 which means, both sides of angles are 20 mm & thickness is 3 mm.

There is no hard rule to calculate the unit weight of Mild steel angles.

Suppose you have 20 m M.S Angles of size 20 x 20 x 3 stacked at your site. And you want to know the total weight of M.S Angles.

Then first you need to find out the unit weight of M.S Angle (20 x 20 x 3). The process of finding the unit weight is very simple. Multiply the Total length of Mild Steel Angles (here 20 m) with unit weight to get the Total weight of M.S Angles stacked at your site.

Unit weight of M.S angle (20 x 20 x 3) is 0.9 kg/m (From Chart)

Total Weight = 20 x 0.9 = 18 KG

Watch Reference Video

Source: Learning Civil Technology

Conclusion

An MS angle weight chart is a helpful tool for designers, material estimators, and architects who are responsible for guaranteeing the structural integrity of buildings. The MS angle weight distribution chart includes the dimensions and related weights per unit length, as well as other important information.

Professionals can precisely assess the weight-bearing capability of various sizes of MS angles, evaluate the amount needed for a project, and make knowledgeable decisions during the design and construction phases by using an MS angle weight chart. For the evaluation of load capacity, material estimate, and cost management, this information is essential.

By minimising material shortages or excess, the weight chart facilitates effective project management and helps to maximise resource utilisation. By supplying the unit weight of MS angles, which is required to determine the overall weight utilised in a project, it permits correct invoicing.

The MS angle weight chart also assists experts in choosing the proper MS angle sizes based on anticipated loads and structural needs, hence promoting structural stability and safety. It enables the development of strong, long-lasting structures and makes correct load distribution possible.

It’s crucial to remember that the precision of weight estimates depends on the given dimensions and the particular quality of mild steel employed. To acquire correct weight information for the MS angles being utilised, it is advised to examine the manufacturer’s specs or weight tables.

Overall, an MS angle weight chart is a useful tool that improves construction projects’ efficiency, precision, and cost-effectiveness. Professionals may use the data the weight chart provides to influence their decisions, optimise the use of materials, and guarantee the successful completion of projects with structural integrity and client satisfaction.

Frequently Asked Questions – FAQs

What is an Mild Steel angle weight chart used for?

An Mild Steel angle weight chart is used to determine the weight of M.S. angles of different sizes, aiding in material estimation, load capacity assessment, and structural design.

How is the unit weight of M.S. angle calculated?

The unit weight is calculated by determining the cross-sectional area of the angle and multiplying it by a constant factor based on the density of M.S. angles.

Why is accurate material estimation important in billing?

Accurate material estimation ensures fair billing, prevents shortages or excess, and helps control project costs effectively.

How does calculating the unit weight help in resource utilization?

Calculating the unit weight helps determine the quantity of Mild Steel angles required, minimizing wastage and optimizing resource utilization.

Can the unit weight of Mild Steel angle vary?

The unit weight may vary depending on the dimensions of the angle and the density of Mild Steel angles used.

Is the unit weight of Mild Steel angle the same as its actual weight?

The unit weight represents the weight per unit length of the Mild Steel angle, whereas the actual weight refers to the total weight of the angle.

How does accurate billing benefit construction projects?

Accurate billing fosters transparency, trust, and maintains a fair billing process, which positively impacts client relationships and project management.

Can an M.S angle weight chart be specific to a manufacturer?

Yes, weight charts may vary slightly depending on the manufacturer and the grade of mild steel used. It’s essential to refer to the specific manufacturer’s weight chart for precise calculations.

Is an MS angle weight chart applicable to other types of steel angles?

An MS angle weight chart is specific to M.S. angles and may not apply directly to other types of steel angles.

Why is it important to follow the calculation methodology?

Following the calculation methodology ensures consistency and accuracy in determining the unit weight of MS angles, leading to precise billing and material estimation.

Mujhko bat krni hai Aapse urgent. 9012626095

Hello Mukesh

I want to work with you

Ur Work is Supprbb

Complet my M-Tech in 2016

& I have No Experience.

So Joine me.

My Whatss app No.is 8959321279.

I am following You from 2 year.

Hi mukesh

your learning experience is best

& I want work with u

So plz… join us

whatsaap no.7033389888

Hello sir,

Sir can u plz upload video for minor or major bridge and box culverts drawings details with reinforcement

Plzzzzz. Sir its very urjent for me

Great job sir… thks for sharing ur knowledge

it's usually a 3rd world based vendor (often not even a manufacturer but a reseller) and experience has shown that if that's the case Bilawal Bashir

Hello shuttering of slab quantity how to calculate sir i m confused sir

Good job

Join me what n.9785236497

Sir please tell me how to find concrete quantity calculation for pier cap and girder in bridge construction

My whatsapp no 9639669692

Plz add me

My whatsapp number 8447211369

Please add me

PLS ADD ME 7708815149

Thanks for sharing this blog.