Sugar is actually a well-known “Retarder” of Concrete and is often used to help in increasing the setting times, especially in emergencies. Tests have shown that 0.06 percent (by weight of cement) of a refined granulated sugar included in a normal mix will increase the setting time by approximately 1-1.5 hours, increase the 7th and 28th-day compressive strengths by about 4 percent, and give a more workable mix for the execution of work. What will happen if we add Sugar in Concrete?

But it is more advisable to use a commercial admixture with known properties supplied by a reputed company. But not all sugars are efficient at retarding cement hydration equally.

NOTE

Trehalose – is a sugar produced by some fungi, yeasts, and similar organisms that are non-retarding and do not affect concrete setting time.

Lactose – “The sugar found in milk”, a simple sugar and is a component of many carbohydrates is a moderate concrete retardant.

Sucrose – It is a Refined white sugar which is mainly found in cane and beet sugar “the sugar that most people put in their/our cup of tea or breakfast cereal”, is one of the best retardants and probably the most effective Concrete Retardant.

Skimmed Milk Powder – It also has a retarding effect on the setting time of concrete due to the sugar present in it.

Another effect of the addition of sugar to fresh concrete is:

Reduction in the peak of heat of hydration – Retarding effect of sugar delays and postpones the conversion of tricalcium silicate crystal hydrates, delays heat hydration of cement and reduces hydration heat peak. hence it reduces the crack in concrete caused by temperature difference.

In mass concreting, while the peak temperature can reach up to 70 degrees Celsius normally, it is reduced to 50-degree celsius upon the addition of sugar.

Sugar, however, is composed of carbon, oxygen and hydrogen atoms which can interfere with the hydration process by binding with the minerals and slow down the reaction.

There are also some theories that the sugar-metal complexes that form can also create an insoluble layer around the cement grains that impedes the reaction necessary for hardening.

Concreting in hot weather above 100°F accelerates the early hydration of

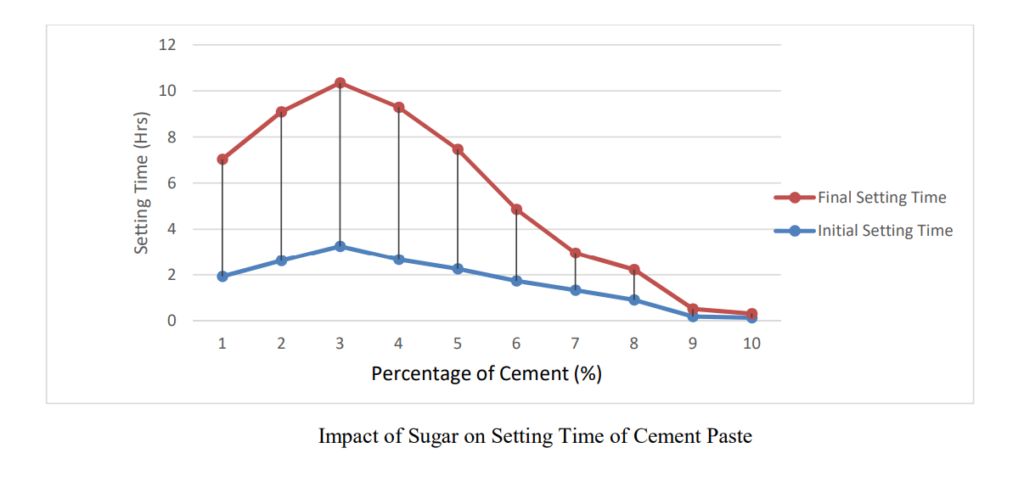

cement and produces concrete with high strength at an early age but later, the strength is reduced considerably. The rapid evaporation of water causes plastic shrinkage in concrete and subsequent cooling causes tensile stresses and cracking. The study seeks to investigate the impact of sugar on setting time of ordinary Portland cement (OPC) paste and compressive strength of concrete.

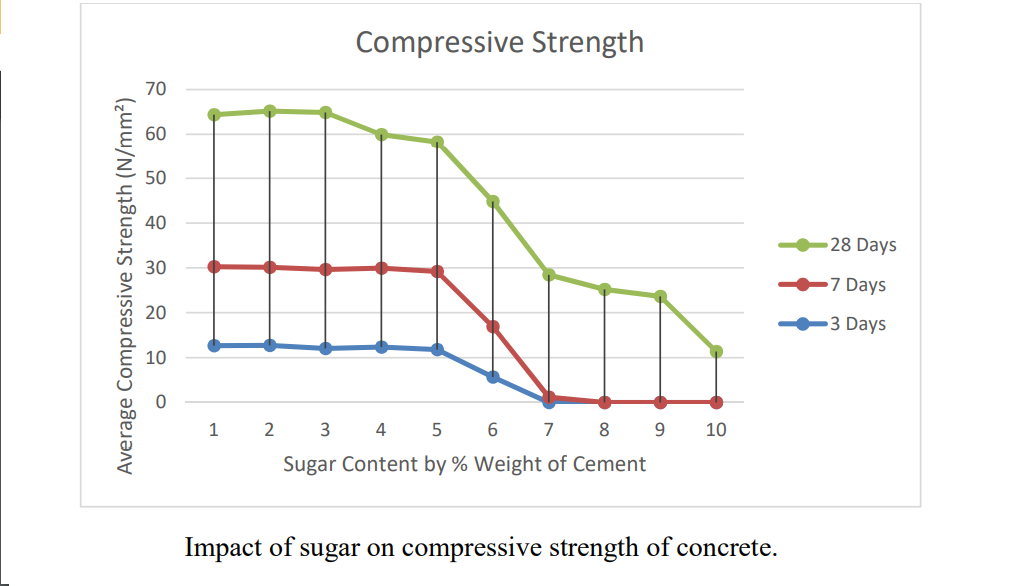

Sugar used for the experiment was sucrose crystals (C12H22O11); it was dissolved in the required amount of water. The sugar was used at concentrations of 0, 0.05, 0.06, 0.08, 0.10, 0.20, 0.40, 0.60, 0.80, and 1% by weight of cement. In addition, the compressive strength of the concrete was investigated at 3, 7

and 21 days. Sugar crystals (C12H22O11) were weighed and dissolved in the required 0.6 volume of water before mixing. The materials were batched by weight and mixed manually.

The increases in initial and final setting times were apparent to the sugar content of 0.06%. Reduction in setting times begins from 0.08% sugar content and flash setting occurs from 0.2% to 1%. There was no correlation between the speed of the setting of cement paste and strength gain from the sugar level of 0.08 to 1%.

Strength gain peaks at 0.05% sugar content at 3 days and at 0.06% sugar content at 7, and 28 days respectively. Sugar delays the setting time of cement by up to 1.33 hours at a dosage level of 0.06% by weight of cement. No effect on workability, compaction by the use of sugar as an admixture in concrete.

Higher long-term compressive strength can be achieved in concrete by the use of sugar as an admixture. The study recommends that sugar should be used as a retarder but when it is used in the excessive amount it reverses its property. The quantity of sugar and other related quantities must be adequately metered in the production process.

Impact of Sugar on Setting Time of Ordinary Portland Cement (OPC)

Results indicate a markedly delay in both the initial and final setting times of cement. The increase in initial and final setting times was obvious to the sugar content of 0.06%. Reduction in setting time begins from 0.08% sugar content and flash setting occurs from 0.2% to 1%.

CONCLUSION

Based on the findings, the study concludes that:

1. Sugar delays the setting time of cement by up to 1.33 hours at a dosage level of 0.06% by weight of cement.

2. There was no effect on the workability and compaction using sugar as an admixture in concrete.

3. Higher compressive strength can be achieved in concrete by the use of sugar as an admixture.

4. The optimum dosage level of sugar as a set-retarding admixture is 0.06% by weight of cement.

5. Consequently, sugar performs satisfactorily as a set-retarding admixture in concrete.

Recommendations

1. Sugar should be used as a retarder but when it is used in excessive amounts, reverse its properties.

2. The quantity of sugar and other related quantities must be adequately measured in the

production process. The sugar content of 0.06% by weight of cement can improve the compressive strength

of concrete by 3.23% at 28 days and delay initial setting time by 1.33 hours (80 minutes).

3. Sugar has no adverse effect on concrete and cement paste.

4. The delay in the setting of concrete at 3 and 7 days for sugar content could be useful in preventing cold

joints and in reducing the early setting of cement in hot weather concreting.

If You Want Detailed Knowledge Then Watch My Video On YouTube Channel: Civil Learning Technology. I Am Telling This Because Many Important Points I Have Covered During Making Of Video, So If You Want To Know In Detail Then Watch My Video On YouTube Which is Given Below.

I hope this article will help you in understanding, why we add Sugar in Concrete? and What will happen if we add Sugar in Concrete?