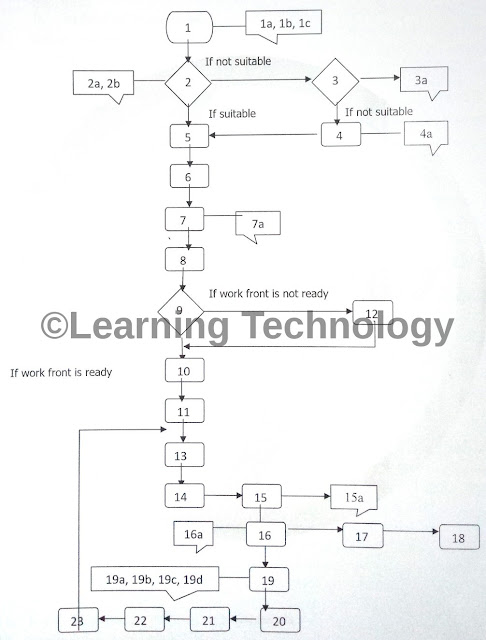

In this post, we will learn about the Flowchart For Aluform Work At Site.

Flowchart For Aluform Work At Site

ACTIVITY FOR THE FLOW CHART NUMBERS

1. Receive Aluform materials.

1a. Packing list, BOQ, and Formwork layout.

1b. Tools.

1c. Additional accessories.

2. Visual inspection.

2a. Packing list & schemes.

2b. Acceptance criteria.

3. Inform concern for any defects.

3a. Details of the report.

4. Collect modification details.

4a. Fabrication drawings.

5. Stock the material as per packing list.

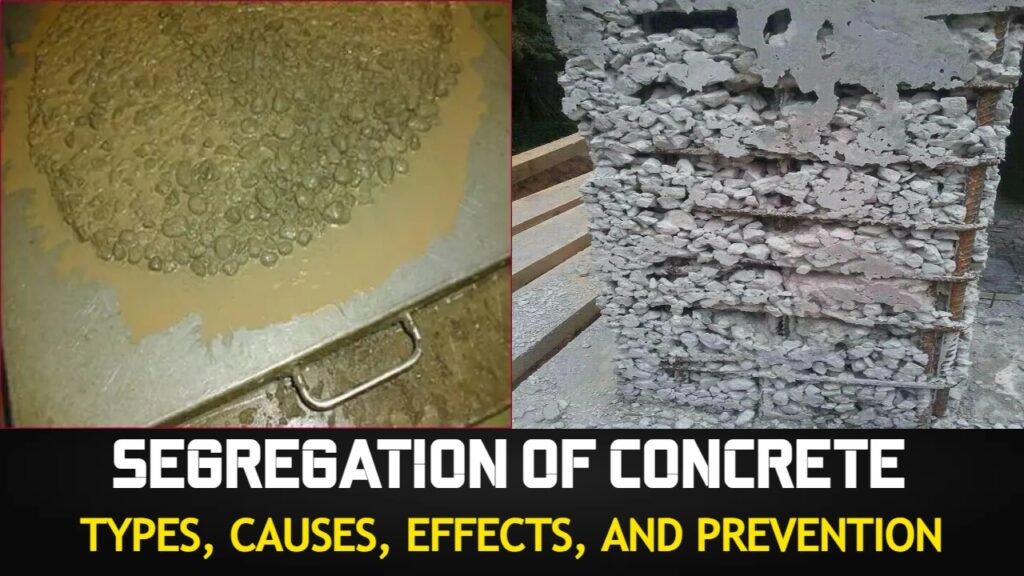

6. Room wise segregation.

7. Dry mock-up.

7a. Schemes.

8. Room wise numbering for identification.

9. Dismantling of mock-up.

10. Setting out.

- STACKING AND STORAGE OF MATERIALS

- Design and Construction Of Pile Foundations

- Evolution of Retaining Structures

- Glossary Relating To Bitumen And Tar

- Aluminium Formwork Refurbishment

- Safety For Hydraulic Tensioning Jacks

- Methodology of Post Tensioning Work

- Properties of Prestressing HT Strand

- Losses in Pre Stress due to Elastic Shortening

- Jack Pressure for Single and Multi Pull Stressing

- Elongation & Modified Elongation in Prestressing

- Prestressing Materials Management at Site

- Prestressing : Definitions | Advantage | Application

- Slipform – Slipform Planning at Site

- Labour Productivity Norms in Slipform

- Dismantling Procedure of Slipform

- Slipform Reinforcement Schedule Planning

- Assembly of Stair Tower for Slipform

- Assembling Procedure of Tapering Slipform

- Assembling Procedure of Straight Slipform

- Classification Of Slip Form Work

- Design Considerations of SlipForm

- Evolution of Slip Form Now a Days

- Measure Horizontal Distance Using AutoLevel

- Bulking OF Fine Aggregates

- Concrete Cube Samples Taken for Different Volume

- Grades of Concrete as per IS 456 : 2000

- Flowchart For Aluform Work At Site

- Dismantling Process of Aluminium Formwork

- Assembling Process of Aluminium Formwork

- Dismantling Of Slab Aluminium Formwork

- Dismantling Of Wall Column & Beam Formwork

- Aluminium Formwork Concreting Process

- Assembling of Wall Aluminium Formworks

- Assembly Process of Aluminium Formwork

- Aluminium Formwork Worksite Management

- What is 1.54 in Concrete

- De Shuttering Period as per IS 456

- Grade Of Concrete And Its Cement, Sand And Aggregate Ratio

- Derivation Of (d²/162) – Unit Weight Of Bar

- Volume Of Different Shapes

11. Shift to the work location.

12. Shift to the stockyard.

13. Actual assembly at work location.

14. Slab rebars & M&E works.

15. Final checking (Pre pour check)

15a. Checklist.

16. Concreting.

16a. Pour card.

17. Post pour check.

18. Levelling and finishing.

19. De-shuttering.

19a. Removing pins and wedges.

19b. Removing wall ties.

19c. Removal of wall panels.

19d. removal of deck panels.

20. Cleaning of panels.

21. Fixing of working platforms with brackets.

22. Erection of safety posts/rails.

23. Applying form release agent.

what is the use of this chart

Sir how to provide construction join in 900mm thick raft foundations