In this post, we will learn about Losses in Pre Stress due to Elastic Shortening.

Contents

Losses in Pre Stress due to Elastic Shortening

Unlike a reinforced concrete member, the strength of a prestressed concrete member is not constant throughout its lifetime. Even if we neglect the deterioration, the prestressing force drops with time due to the time-dependent losses.

Hence, the calculation of the losses is very important in prestressed concrete applications. In the prestressed concrete applications, the most important variable is the prestressing force. In the earlier days, it was observed that the prestressing force does not stay constant, but it reduces with time.

Even during prestressing of the tendons and the transfer of prestress to the concrete member, there is a drop of the prestressing force from the recorded value in the jack gauge. The various reductions of the prestressing force are termed as losses in prestressing.

Different Sections of Losses

In this chart, we are trying to understand the various losses under different sections. The losses in prestressing can broadly be classified under two groups: one is the immediate losses, which are shown on the left side. The other is the time-dependent losses, which takes several years until the prestressing force gets stabilized.

Out of immediate losses, the important one is the elastic shortening, which is the shortening of the concrete member when the prestressing force is transferred to it. It is an immediate shortening. Then, the second one is friction. The friction is the drop in the prestressing force along the length of the prestressing tendon, because of the curvature in the prestressing tendon. The third one is the anchorage slip.

- STACKING AND STORAGE OF MATERIALS

- Design and Construction Of Pile Foundations

- Evolution of Retaining Structures

- Glossary Relating To Bitumen And Tar

- Aluminium Formwork Refurbishment

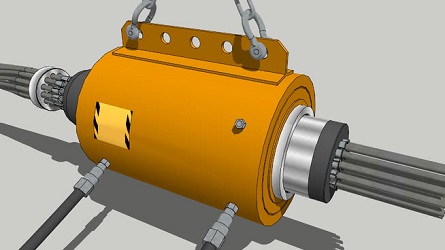

- Safety For Hydraulic Tensioning Jacks

- Methodology of Post Tensioning Work

- Properties of Prestressing HT Strand

- Losses in Pre Stress due to Elastic Shortening

- Jack Pressure for Single and Multi Pull Stressing

- Elongation & Modified Elongation in Prestressing

- Prestressing Materials Management at Site

- Prestressing : Definitions | Advantage | Application

- Slipform – Slipform Planning at Site

- Labour Productivity Norms in Slipform

- Dismantling Procedure of Slipform

- Slipform Reinforcement Schedule Planning

- Assembly of Stair Tower for Slipform

- Assembling Procedure of Tapering Slipform

- Assembling Procedure of Straight Slipform

- Classification Of Slip Form Work

- Design Considerations of SlipForm

- Evolution of Slip Form Now a Days

- Measure Horizontal Distance Using AutoLevel

- Bulking OF Fine Aggregates

- Concrete Cube Samples Taken for Different Volume

- Grades of Concrete as per IS 456 : 2000

- Flowchart For Aluform Work At Site

- Dismantling Process of Aluminium Formwork

- Assembling Process of Aluminium Formwork

- Dismantling Of Slab Aluminium Formwork

- Dismantling Of Wall Column & Beam Formwork

- Aluminium Formwork Concreting Process

- Assembling of Wall Aluminium Formworks

- Assembly Process of Aluminium Formwork

- Aluminium Formwork Worksite Management

- What is 1.54 in Concrete

- De Shuttering Period as per IS 456

- Grade Of Concrete And Its Cement, Sand And Aggregate Ratio

- Derivation Of (d²/162) – Unit Weight Of Bar

- Volume Of Different Shapes

After the jacks have pulled the tendons and the wedges are placed, the tendons are released. At that instant, the wedges and the anchorage block seat in the prestressed member. During the seating, there is some loss until the wedges get locked in the anchorage block. The loss due to this seating of the anchorage is called the ‘anchorage slip’.

Among the time-dependent losses, we have already studied the phenomena under the material properties. Creep and shrinkage are typical behaviours of concrete. Creep is the deformation with time under a constant load. Shrinkage is the deformation with time due to loss of moisture. Relaxation is a property of the prestressing steel, which is the drop in the stress under a constant strain, with time. In today’s lecture, the following section will quantify the loss due to elastic shortening.

In pre-tensioned members, when the tendons are cut and the prestressing force is transferred to the member, the concrete undergoes immediate shortening due to the prestressing force. The tendons also shorten by the same amount, which leads to the loss of prestress. The elastic shortening is more of a concern in a pre-tensioned member.

In post-tensioned members, the phenomenon of elastic shortening is different from that in pre-tensioned member. If there is only one tendon, then there is no loss because the applied prestress is recorded after the elastic shortening of the member.

In post-tensioned members, as the jack gets the reaction from the concrete member itself when the jack is applying tension in the tendon, the member is shortening. After the shortening stabilises, we are recording the final force. Hence, we do not consider the elastic shortening as a loss, because we are recording the prestressing force after the concrete member has shortened.

This is true if we have just one tendon for post-tensioning the member. But, if we are having more than one tendon, then when we are applying tension to a subsequent tendon, the tendons which we have tensioned earlier, they will be undergoing some elastic shortening. For more than one tendon, if the tendons are stretched sequentially, there is a loss in a tendon during subsequent stretching of the other tendons.

How do we calculate the loss in prestressing due to elastic shortening?

The elastic shortening loss is quantified by the drop in the prestressing force in a tendon, due to the change in strain in the tendon. It is obvious from Hooke’s law, that if we have a change in strain, there will be a change in the stress. What we are trying to quantify is the change in the strain. It is assumed that the change in strain in the tendon is equal to the strain in concrete at the level of the tendon due to the prestressing force. This assumption is called strain compatibility between concrete and steel.

For a pre-tensioned member, there is a bond between the prestressing tendon and the concrete. For a post-tensioned member, there is a bond when we are grouting the post-tensioned members and hence, we can consider strain compatibility between the concrete and the steel. Whatever the strain the concrete undergoes at the level of the steel, the same strain is reflected in the prestressing tendon. The prestressing tendon also undergoes the same change in the strain is equal to the strain in the concrete.

Losses in Pre-Stress

- Losses due to Elastic Shortening of Concrete

- Creep in Concrete (Creep Strain)

- Shrinkage in Concrete

- Relaxation of Pre-stressing Steel

- Losses due to the seating of Anchorages

- Friction Losses

I hope you find this information useful. If there is something that I have missed or I do not know, you can comment and tell me which I will try to rectify as soon as possible.

If you have liked this post of mine, then use the social link given below and share it among your friends on social media. Thanks

SHARE THIS POST, IF YOU LIKE IT !!

Padhega India Tab Hi Badhega India | पढ़ेगाइंडियातबहीबढ़ेगाइंडिया