Hello Friends, This is Mukesh from Learning Technology. I will tell you in today’s post, Determination of Flakiness and Elongation Index of Coarse Aggregates in a very easy way.

Contents

Object of Experiment

To determine the Flakiness and Elongation Index of Coarse Aggregates.

Theory and Scope

The particle shape of aggregates is determined by the percentage of flaky (layered) and elongated particles contain in it. For base course and construction of bituminous and cement concrete types, the presence of flaky and elongated particles are considered undesirable as they may cause inherent weakness with possibilities of breaking down under heavy loads. Rounded aggregates are performed in cement concrete road construction as the workability of concrete improves. Angular shapes of particles are desirable for a granular base course due to increased stability derived from the better interlocking. Thus the evaluation of the shape of the particles, particularly concerning flakiness, elongation is necessary.

Flakiness Index

The flakiness index of aggregates is the percentages by weight of particles whose least dimension (thickness) is less than 3/5th (0.6) of their mean dimension. The test does not apply to sizes smaller than 6.3 mm.

[For example, the mean sieve size for an aggregate piece passing through 50 mm and retained on 40 mm sieve is (50+40)/2 i.e. 45 mm. If the least lateral dimension is less than (0.6 x 45) = 27 mm, the aggregate is classified as flaky]

Equipment

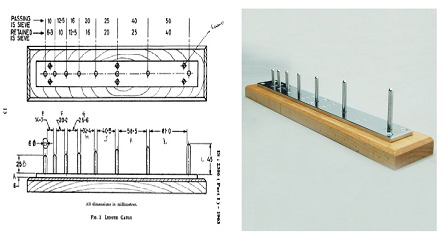

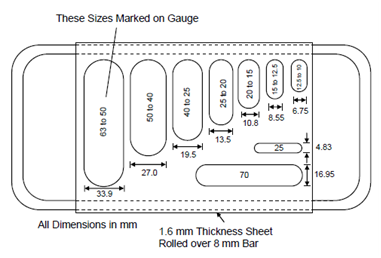

The Apparatus consists of a standard thickness gauge, IS Sieves of sizes 63, 50, 40, 31.5, 25, 16, 12.5, 10 and 6.3 mm and a balance to weigh the samples.

Procedure

The sample is sieved with the sieves mentioned in the table as a minimum of 200 pieces of each fraction to be tested are taken and weighed = W1 gram to separate flaky materials, each fraction is then gauged for thickness on a thickness gauge or in bulk on sieves having elongated slots. The width of the slot used should be of the dimensions specified in column (3) of the table (a) for the appropriate size of the materials. The amount of flaky material passing the gauge is weighed to an accuracy of at least 0.1 % of the test sample.

Table (a) (Dimensions of Thickness and Length Gauges)

| Size of Aggregate | (a) Thickness Gauge (0.6 times the mean sieve), mm | (b) Length Gauge (1.8 times the mean sieve), mm | |

| Passing through IS Sieve (mm) | Retained on IS Sieve (mm) | ||

| (1) | (2) | (3) | (4) |

| 63.00 | 50.00 | 33.90 | – |

| 50.00 | 40.00 | 27.00 | 81.00 |

| 40.00 | 25.00 | 19.50 | 58.50 |

| 31.50 | 25.00 | 16.95 | – |

| 25.00 | 20.00 | 13.50 | 40.50 |

| 20.00 | 16.00 | 10.80 | 32.40 |

| 16.00 | 12.50 | 8.55 | 25.60 |

| 12.50 | 10.00 | 6.75 | 20.20 |

| 10.00 | 6.30 | 4.89 | 14.70 |

Calculation and Result

To calculate the flakiness index of the entire sample of aggregates, the first weight of each fraction of aggregate passing and retained on the specified set of sieves is noted. As an example, Let 200 pieces of the aggregate passing 50 mm sieve and retained on 40 mm sieve be = W1 gram. Each of the particles from this fraction of aggregate is tired to be passed through the slot of the specified thickness of the thickness angle; in this example, the width of the appropriate gauge of the thickness gauge is = ((50+40)/2)*0.6 = 27 mm gauge.

Let, the weight of the flaky material passing this gauge be W1 gram. Similarly, the weights of the fractions passing and retained the specified sieves, W1, W2, W3, ….. etc. also the weights of the material passing each of the specified thickness gauges are found = w1, w2, w3, ….. then the flakiness index is the total weight of the flaky material passing the various thickness gauges expressed as a percentage of the total weight of the sample gauged.

READ MORE

- Stripping Value of Road Aggregate by Dynamic Immersion Method

- Determination of Efficiency of a Centrifugal Pump

- Calibration of V-Notch Experiment

- Aggregate Impact Value Test as per IS 2386 (Part-IV) 1993

- Aggregate Crushing Value Test

- Water Content of Soil by Oven Drying Method

- Specific Gravity of Cement by Specific Gravity Bottle

- Sp. Gravity & Water Absorption Of Coarse Aggregate

- Sp. Gravity & Water Absorption of Fine Aggregates

Elongation Index

The Elongation Index of an aggregate is the percentage by weight of particles whose greatest dimension (length) is greater than 1.8 times their mean dimension. The elongation test does not apply to sizes smaller than 6.3 mm.

Equipment

The Apparatus consists of the length gauge, sieves of the sizes specified in Table (a) and a balance

Procedure

The sample is saved through the IS Sieves specified in table (a). A minimum of 200 pieces of each fraction is taken and weighted. To separate elongated material, each fraction is then gauged individually for length in a length gauge. The gauge length used should be those specified in column (4) of the table (a) for the appropriate material. The pieces of aggregates from each fraction tested which could not pass through the specified gauge length with its long side are elongated particles and are collected separately to find the total weight of aggregates retained on the length gauge from each fraction. The total amount of elongated materials retained by the length gauge is weighted to an accuracy of at least 0.1 percent of the weight of the test sample.

Calculation and Result

To calculate the Elongation Index of the entire sample of aggregates, the weight of aggregates which is retained on the specified gauge length from each fraction is noted. As an example, Let 200 pieces of the aggregate passing 40 mm sieve and retained on 25 mm sieve weight W1 gram. Each piece of these is tried to be passed through the specified gauge length of the length gauge, which in this example is ((40+25)/2) x 1.8 = 58.5 mm.

With its longest side and those elongated pieces which do not pass the gauge is separated and the total Weight determined = W1 gram. Similarly, the weight of each fraction of aggregate passing and retained on specified sieve sizes are found, W1, W2, W3, ….. Also, the weight of the materials from each fraction retained on the specified gauge length is found = X1, X2, X3, ….. The Elongation Index is the total weight of the material retained as a percentage of the total weight of the sample gauged.

Elongation Index = ((X1 + X2 + X3 + …..) x 100) / (W1 + W2 + W3 + …..)

Discussions and Conclusions

The main objective of this test is to determine the relative amounts of flaky and elongated particles which when present in large quantity may result in more voids in the concrete, thus requiring a large amount of sand, cement, and water for particular workability. These particles tend to be oriented on one plane which affects the durability. Generally, elongated or flaky particles above 10 to 15% are not desirable. The test does not apply to sizes smaller than 6.3 mm. The Elongation and Flakiness Index are found to be ………………..