In this post, we will learn about Aluminium Formwork Refurbishment Process in full details step by step.

Contents

Aluminium Formwork Refurbishment

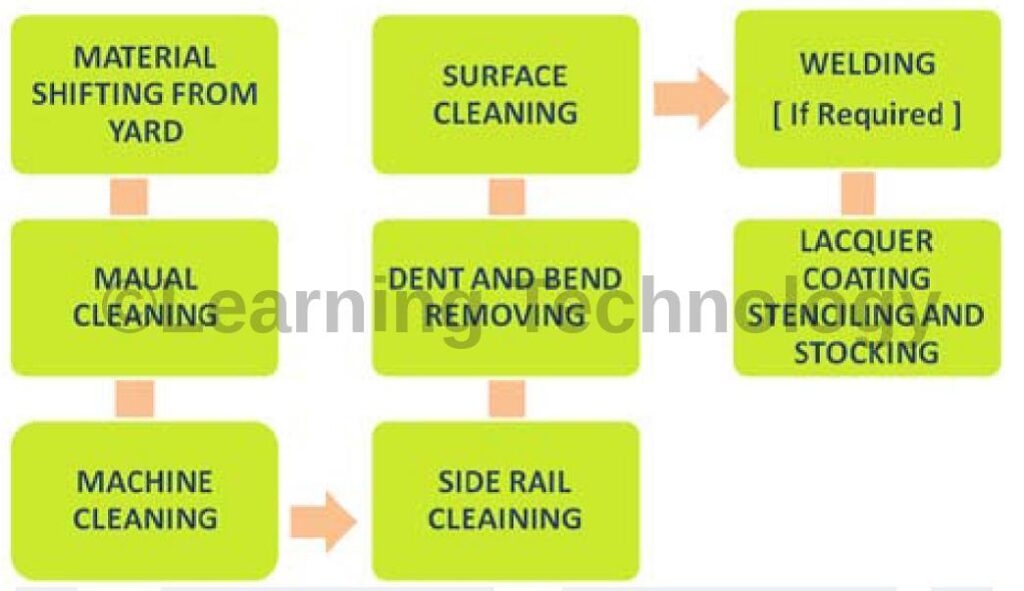

Process Involved

STEP 1: Material shifting from the yard

STEP 2: Surface Cleaning

STEP 3: Welding (If Required)

STEP 4: Manual Cleaning work

STEP 5: Dent and Bend Removing

STEP 6: Lacquer Coating Stenciling and Stocking

STEP 7: Machine Cleaning work

STEP 8: Side Rail Cleaning work

A) Manual Cleaning

A working table to be made and the Concrete lumps, dirt shall be cleaned by the scraper and wire brush.

- STACKING AND STORAGE OF MATERIALS

- Design and Construction Of Pile Foundations

- Evolution of Retaining Structures

- Glossary Relating To Bitumen And Tar

- Safety For Hydraulic Tensioning Jacks

- Methodology of Post Tensioning Work

- Properties of Prestressing HT Strand

- Losses in Pre Stress due to Elastic Shortening

- Jack Pressure for Single and Multi Pull Stressing

- Elongation & Modified Elongation in Prestressing

- Prestressing Materials Management at Site

- Prestressing : Definitions | Advantage | Application

- Slipform – Slipform Planning at Site

- Labour Productivity Norms in Slipform

- Dismantling Procedure of Slipform

- Slipform Reinforcement Schedule Planning

- Assembly of Stair Tower for Slipform

- Assembling Procedure of Tapering Slipform

- Assembling Procedure of Straight Slipform

- Classification Of Slip Form Work

- Design Considerations of SlipForm

- Evolution of Slip Form Now a Days

- Measure Horizontal Distance Using AutoLevel

- Bulking OF Fine Aggregates

- Concrete Cube Samples Taken for Different Volume

- Grades of Concrete as per IS 456 : 2000

- Flowchart For Aluform Work At Site

- Dismantling Process of Aluminium Formwork

- Assembling Process of Aluminium Formwork

- Dismantling Of Slab Aluminium Formwork

- Dismantling Of Wall Column & Beam Formwork

- Aluminium Formwork Concreting Process

- Assembling of Wall Aluminium Formworks

- Assembly Process of Aluminium Formwork

- Aluminium Formwork Worksite Management

- What is 1.54 in Concrete

- De Shuttering Period as per IS 456

- Grade Of Concrete And Its Cement, Sand And Aggregate Ratio

- Derivation Of (d²/162) – Unit Weight Of Bar

- Volume Of Different Shapes

A.1) Tools Required

- Ball Pein Hammer

- Chisel

- Scrapper

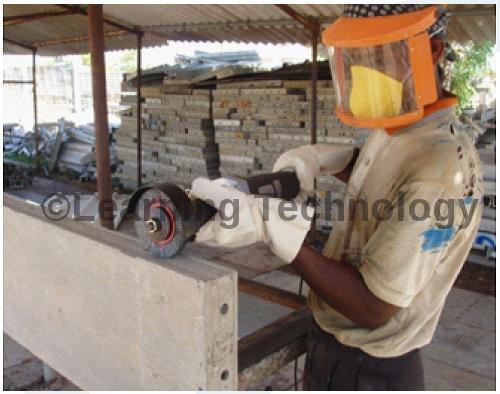

B) Machine Cleaning

Side rails are cleaned with GQ4 Grinding Machine, 4” circular buffing wheel.

B.1) Tools Required

- GQ 4 Grinding Machine

- 4” circular buffing wheel

- 6” RUBBER BACK UP PAD

C) Dent Removal

Remove the Dents if any in the panel using a hammer and a flat base plate. Make sure that no point contact is there during this process.

Click here for Civil Engineering Videos

D) Welding

After removing the dents, inspect the panel for any cracks in the welding joints. If found it shall be welded.

D.1) Tools Required

- TIG Welding machine

- Welding coil spec: Aluminium filler wire 1.2 mm. Er 5356. Make: Indaco

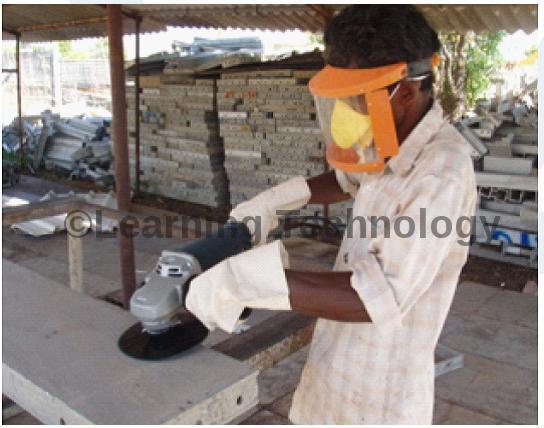

E) Surface Cleaning

Surface cleaning shall be done with the sander disc, ensure that smooth rendering only is done.

E.1) Tools Required

- AG7 & AG4 GrindingMachine ( RPM – 5000)

- Sander Disc (80/120 Grade)

F) Lacquering and Stenciling

Brushing viscosity of lacquer can be 30 sec. Surface to be touch dry within 10 min of application. Allow overnight and use. Thinner- MCC 2507.

Safety items

- Hand gloves

- Nose mask

- Earplug/earmuff

- Apron

- Goggles – white

I hope you find this information useful. If there is something that I have missed or I do not know, you can comment and tell me which I will try to rectify as soon as possible.

If you have liked this post of mine, then use the social link given below and share it among your friends on social media. Thanks

SHARE THIS POST, IF YOU LIKE IT !!

Padhega India Tab Hi Badhega India | पढ़ेगा इंडिया तब ही बढ़ेगा इंडिया