Hello Friends, This is Mukesh from Learning Technology. I will tell you in today’s post, Bitumen Penetration Test – Consistency Test of Bituminous Material in a very easy way.

Contents

Object of Experiment

To determine the consistency of bituminous material and assess its suitability for its use under different climatic conditions and types of construction.

Theory and Scope

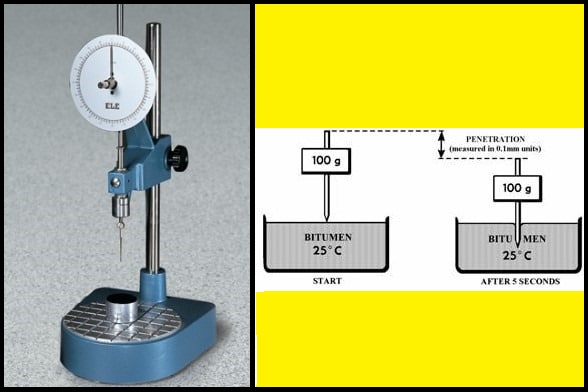

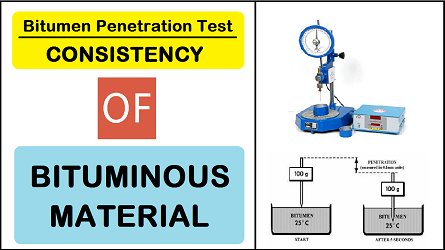

Penetration test measures the hardness for consistency (softness) of bituminous material by measuring the depth in tenths of a millimeter to which a standard loaded needle will penetrate vertically into a sample of the material under standard conditions of temperature, in 5 seconds. The concept of a Penetration test is illustrated in the figure. The test helps in establishing and verifying the grade of bitumen. This test is conducted as per IS 1203 – 1978.

Equipment

Penetrometer

A cylindrical container and a needle

Water bath and bath thermometer

Transfer dish or Tray

READ MORE

- Softening Point of Bituminous Materials

- Aggregate Abrasion Value Test

- Flash and Fire Points of Bituminous Materials

- Determination of Flakiness and Elongation Index of Coarse Aggregates

- Stripping Value of Road Aggregate by Dynamic Immersion Method

- Determination of Efficiency of a Centrifugal Pump

- Calibration of V-Notch Experiment

Description of Equipment

> Penetrometer calibrated to give accurate results in one-tenth of a millimeter allows the needle to penetrate without much friction. The penetrometer has leveling screws and spirit level to make the base horizontal. The needle is secured in a vertical position and the total weight of needle assembly is 100 grams. A knob is used to release or lock the needle assembly. The needle penetration is measured on a dial graduated in one-tenth of a millimeter. An automatic type penetrometer is provided with an electric timer that releases the needle exactly for 5 seconds.

> Container is a flat bottomed cylindrical metallic dish 55 mm in diameter and 35 mm in depth. If the penetration is of the order of 25 mm or more, a deeper dish of 70 mm diameter and 45 mm depth is used.

> Needle consists of a straight, highly polished, cylindrical hard steel rod.

> Water bath maintained at 25 degrees Celsius ± 0.1 degree Celsius containing not less than 10 liters of water, the sample is immersed to a depth not less than 100 mm from the top and supported on a perforated shelf not less than 50 mm from the bottom of the bath.

> Bath thermometer of range 0 to 44 degrees Celsius with 0.2 degree Celsius graduations.

> Time measuring device with an accuracy of ± 0.1 seconds.

Transfer dish or Tray for supporting the container and should not rock the container. It should be of such capacity as to completely immerse into the container during the test.

Procedure

1. Soften the material to a pouring consistency by heating it at a temperature not more than 90 degrees Celsius for bitumen and 60 degrees Celsius for tars above the approximate softening point. Stir it thoroughly until it is homogeneous and is free from air bubbles and water.

2. Pour the melted bitumen into the container to a depth of at least 15 mm in excess of expected penetration at 25 degrees Celsius.

3. Protect the sample from dust and allow it to cool in an atmospheric temperature between 15 degrees Celsius to 30 degrees Celsius for 1 ∼ hour. Then place it in a transfer dish in the water bath at 25 ± 0.1 degrees Celsius for 1 to 1 and a half hours.

4. Fill the transfer dish with water from the water bath to depth sufficient to cover the container completely, place the sample in it and keep the container on the stand of the penetration apparatus.

5. Clean the needle with benzene, dry it and load with the weight. The total moving load required is 100 ± 0.25 grams. This includes the weight of the needle, carrier and super-imposed weights.

6. Adjust the needle to make contact with the surface of the sample. This may be done by placing the needlepoint in contact with its image reflected by the surface of the bituminous material.

7. Adjust the pointer of the dial to read zero or note the initial dial reading.

8. Release the needle for exactly 5 seconds. The release of the needle can be secured with the help of an automatic electric timer. The needle is locked after 5 seconds, the use of timer minimizes human error.

9. Adjust the rack of penetration dial to measure the distance penetrated in one-tenth of a millimeter.

10. Repeat the above procedure at least thrice at points on the surface of the sample not less than 10 mm apart and not less than 10 mm from the side of the dish. After each test returns the sample and transfer dish to the water bath and wash the needle clean with benzene and dry it. In the case of the material of penetration greater than 25 mm, three determinations on each of the two identical test specimens using a separate needle for each determination should be made, leaving the needle in the sample on completion of each determination to avoid disturbance of the specimen.

The value of penetration should be the mean of not less than three determinations expressed in tenths of a millimeter.

READ MORE

- Aggregate Impact Value Test as per IS 2386 (Part-IV) 1993

- Aggregate Crushing Value Test

- Water Content of Soil by Oven Drying Method

- Specific Gravity of Cement by Specific Gravity Bottle

- Sp. Gravity & Water Absorption Of Coarse Aggregate

- Sp. Gravity & Water Absorption of Fine Aggregates

Observations

| Test Temperature | |||

| Penetrometer Dial Reading |

(I) |

(II) |

(III) |

| a. Initial | |||

| b. Final | |||

| Penetration Value | |||

| Mean Penetration Value | |||

Precaution

1. Wear safety glasses and/or face shields, heat resistant gloves with close-fitting cuffs.

2. There shall be no smoking or the presence of other ignition sources in close proximity of test set up.

3. Check the samples for the presence of water while the material is still cold. If water is present drain off as much water as possible and allows the sample to dry at room temperature or blow-dry with clean compressed air.

4. There should be no movement of the container while the needle is penetrating into the sample.

5. Bitumen sample should be just sufficient to fill the container to a depth of at least 15 mm in excess of the expected penetration.

6. The needle should be cleaned with benzene and dried before each penetration.

7. It is important to maintain the test temperature at the specified level during testing.

Discussions

It may be noted that penetration value is largely influenced by any inaccuracy with regards to pouring temperature, size of the needle, weight placed on the needle and the test temperature. The penetration test is a commonly adopted test on bitumen to grade the material in terms of its hardness or consistency. For example, S-90 (801100) grade bitumen indicates that its penetration value lies between 80 and 100. The grading of bitumen helps to assess its suitability for use in different climatic conditions and types of construction. For bituminous macadam and penetration macadam, IRC suggests 35, 65 and 90 bitumen grades. For semi dense bituminous concrete (SCDC) with bitumen emulsion concrete (BC) usually, 65 grade is used. For mastic asphalt, the harder grade is used. In hot climates, a lower penetration grade is preferred to avoid softening whereas higher penetration grades are used in cold regions so that excessive brittleness does not occur. The highest penetration grade is used in spray application work. The penetration values of various grades are listed in Table.

Penetration range for various grades of bitumen

| Bitumen Grade: S | S-35 | S-45 | S-55 | S-65 | S-90 | S-200 |

| Bitumen Grade: A | A-35 | – | A-55 | A-65 | A-90 | – |

| Penetration Range | 30-40 | 40-50 | 50-60 | 60-70 | 80-100 | 175-225 |

Well explained bro. Keep it up.

Thanks