In this post, we will learn about the Design Considerations of SlipForm

Design Considerations of SlipForm

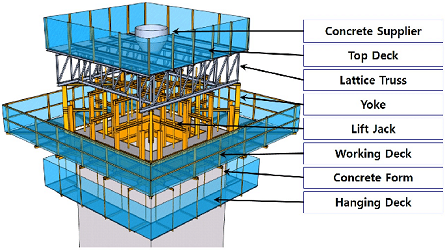

The Slipform should be designed so that the loads to which its various component parts are subjected are uniformly distributed, and the yokes are loaded as uniformly and axially as possible to avoid their overturning. The jacks should not be located in wall openings as for as possible. The loading should not exceed the lifting capacity of the jacks.

The loads acting on Slipform can be classified as follows,

A. Basic Loads

1. Dead load due to the components

2. Live loads due to Concrete

3. Friction between form and concrete

4. Workmen

5. Materials

6. Machinery

7. Other installations

8. Auxiliary load due to the way of application of live loads

9. Crowds of workmen

10. Piles of materials

11. Shocks produced by material unloading

- STACKING AND STORAGE OF MATERIALS

- Design and Construction Of Pile Foundations

- Evolution of Retaining Structures

- Glossary Relating To Bitumen And Tar

- Aluminium Formwork Refurbishment

- Safety For Hydraulic Tensioning Jacks

- Methodology of Post Tensioning Work

- Properties of Prestressing HT Strand

- Losses in Pre Stress due to Elastic Shortening

- Jack Pressure for Single and Multi Pull Stressing

- Elongation & Modified Elongation in Prestressing

- Prestressing Materials Management at Site

- Prestressing : Definitions | Advantage | Application

- Slipform – Slipform Planning at Site

- Labour Productivity Norms in Slipform

- Dismantling Procedure of Slipform

- Slipform Reinforcement Schedule Planning

- Assembly of Stair Tower for Slipform

- Assembling Procedure of Tapering Slipform

- Assembling Procedure of Straight Slipform

- Classification Of Slip Form Work

- Design Considerations of SlipForm

- Evolution of Slip Form Now a Days

- Measure Horizontal Distance Using AutoLevel

- Bulking OF Fine Aggregates

- Concrete Cube Samples Taken for Different Volume

- Grades of Concrete as per IS 456 : 2000

- Flowchart For Aluform Work At Site

- Dismantling Process of Aluminium Formwork

- Assembling Process of Aluminium Formwork

- Dismantling Of Slab Aluminium Formwork

- Dismantling Of Wall Column & Beam Formwork

- Aluminium Formwork Concreting Process

- Assembling of Wall Aluminium Formworks

- Assembly Process of Aluminium Formwork

- Aluminium Formwork Worksite Management

- What is 1.54 in Concrete

- De Shuttering Period as per IS 456

- Grade Of Concrete And Its Cement, Sand And Aggregate Ratio

- Derivation Of (d²/162) – Unit Weight Of Bar

- Volume Of Different Shapes

B. Accidental Loads

1. Wind pressure

2. Adhesion between concrete and form due to long interruption

3. Friction due to incorrect position of the form

4. Failure of one jack

5. Extraordinary Loads

6. Breaking of certain members of the slip form

7. Failure of two adjacent jacks

Minimum concrete strength required for Slipform application,

2 Kg / cm2 – When releasing the Form

4 Kg / cm2 – When coming out from the Form

20 Kg / cm2 – After 24 hours since pouring

200 Kg / cm2 – After 28 days

I hope you find this information useful. If there is something that I have missed or I do not know, you can comment and tell me which I will try to rectify as soon as possible.

If you have liked this post of mine, then use the social link given below and share it among your friends on social media. Thanks

SHARE THIS POST, IF YOU LIKE IT !!

Padhega India Tab Hi Badhega India | पढ़ेगा इंडिया तब ही बढ़ेगा इंडिया