Hello Friends, This is Mukesh from Learning Technology. I will tell you in today’s post, Determination of Normal Consistency of Cement in a very easy way.

Contents

Objective of Experiment

To determine the Normal Consistency for a given sample of cement.

Performance Objectives

a) To define the normal consistency of cement.

b) To prepare a cement paste.

c) To set up the experiment.

d) To follow the procedural steps with precautions.

e) To fill up the observation table appropriately.

f) To report as per instruction.

Theory

Normal Consistency of cement is defined as a percentage of water by weight of cement which produces a cement paste of standard consistency permitting a standard plunger of 10 mm diameter to penetrate up to a depth of 5 mm to 7 mm above the bottom of Vicat’s Mould. The percentage of water in the cement paste for standard consistency will vary from cement and from batch to batch of the same cement. Normal consistency generally ranges from 26 to 33 expressed as a percentage by weight of dry cement. Many times higher normal consistency values are observed for old cement or if the cement is to fine (very high specific surface area).

READ MORE

- Specific Gravity Test for Bitumen

- Bitumen Penetration Test – Consistency Test

- Softening Point of Bituminous Materials

- Aggregate Abrasion Value Test

- Flash and Fire Points of Bituminous Materials

- Determination of Flakiness and Elongation Index of Coarse Aggregates

- Stripping Value of Road Aggregate by Dynamic Immersion Method

- Determination of Efficiency of a Centrifugal Pump

- Calibration of V-Notch Experiment

Necessary Equipment Required

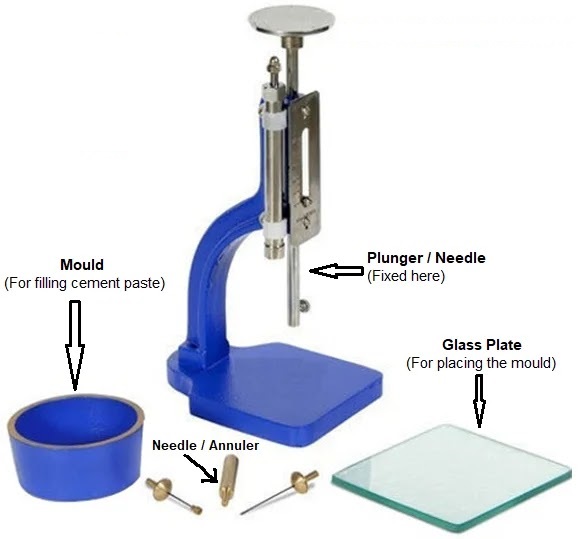

1) Vicat-apparatus with the plunger of 10 mm diameter and 50 mm long and Vicat’s mould with mild steel base plate.

2) Balance with weights (capacity 1 kg, the sensitivity up to 0.1 gram)

3) Trowel (small, weighing about 210 gm)

4) Marble stone slab (non-porous plate)

5) Enamel tray.

6) Measuring glass (100 cc – 2 numbers)

7) Thermometer range (50 degree Celsius)

8) Stopwatch

9) Standard spatula

Specimen supplied

Portland cement = 400 gram (for each trial)

Preparation of Cement Paste

a) Weigh about 400 grams of dry cement accurately and place it in the enamel tray.

b) Add 25% of clean water and mix it uniformly by means of a spatula.

c) Care should be taken that the time of mixing (gauging) is not less than 3 minutes and not more than 5 minutes. The gauging time shall be counted from the instant of adding water to the dry cement until commencing to fill the mould.

READ MORE

- Aggregate Impact Value Test as per IS 2386 (Part-IV) 1993

- Aggregate Crushing Value Test

- Water Content of Soil by Oven Drying Method

- Specific Gravity of Cement by Specific Gravity Bottle

- Sp. Gravity & Water Absorption Of Coarse Aggregate

- Sp. Gravity & Water Absorption of Fine Aggregates

Experimental setup

The Vicat plunger, made up of polished brass, 10 mm diameter, 50 mm long with a threaded projection at the upper end for fixing into the movable rod and also having the lower age flat, shall be fixed to the Vicat apparatus in a proper position. The plunger when resting on the non-porous plate at the bottom of the mould should indicate a reading of zero in its scale.

Procedure

1) Fill the Vicat mould with the cement paste, the mould resting on a marble slab, or not displayed.

2) Make the surface of the cement paste in level with the top of the mould with a trowel weighing about 210 grams. The mould should be slightly shaken to expel air bubbles.

3) Place this mould together with the non-porous plate under the rod bearing plunger. Bring the bottom of the plunger gradually to the surface of the cement paste.

4) Release the plunger quickly, allowing it to sink into the paste. A reading of 5 to 7 mm is desired for the normal consistency of the cement paste. In case the reading is different, continue with the following steps.

5) Prepare trial pastes with varying percentages of water and the test as described above until the plunger penetrates up to a depth of 5 mm to 7 mm above the bottom of the mould.

6) Indicate this amount of water as a percentage by weight of dry cement (normal consistency).

Precautions

1) The temperature of cement, water, and that of the test room at the time of the test should be between 25 degrees to 29 degrees Celsius.

2) Appliances to be used for gauging should be neat and clean.

3) The gauging time must be between 3 to 5 minutes.

4) In filling the mould, the operator’s hand and the blade of the trowel along be used.

5) Plunger and mould must be clean from each training trial.

Observation Table

| Sl. No. | Type of Cement | Manufactured By | Weight of Cement Sample | Percentage of Water Added | Quantity of water added | Unpenetrated Depth in mm |

Report

1) Specimen calculations: Calculations for a percentage of water added is to be given.

2) Results: Normal consistency (percentage of water by weight of dry cement) = …………… %

3) Drawing sketches of apparatus.

4) Conclusion / Discussion: (Comments on results, comparing with standard values)

If You Want Detailed Knowledge Then Watch My Video On YouTube Channel: Civil Learning Technology. I Am Telling This Because Many Important Points I Have Covered During Making Of Video, So If You Want To Know In Detail Then Watch My Video On YouTube Which is Given Below.

Hi! Its great to be here as a part of your blog community. But why dont you replay any of my comments? It is good to interact with the people who interest in your post.

I always reply to you post. U can Check