Hello Friends, This is Mukesh from Learning Technology. I will tell you in today’s post, Determination of Initial and Final Setting Time of Cement as per IS 4031 PART-5, in a very easy way.

Contents

Objective of Experiment

To determine the initial and final setting time of a given cement sample

Performance Objectives

a) To explain the theory of setting of cement

b) To explain initial and final setting time

c) To prepare a cement paste

d) To set up the Apparatus

e) To follow the procedural steps with precautions

f) To fill up the observation table appropriately

g) To report as per instructions

ALSO READ

- Compressive Strength Test of Cement

- Fineness Modulus of a Sample of Fine Aggregate

- Determination of Normal Consistency of Cement

- Specific Gravity Test for Bitumen

- Bitumen Penetration Test – Consistency Test

- Softening Point of Bituminous Materials

- Aggregate Abrasion Value Test

Theory

The term setting of cement is used to describe the stiffening of cement paste. When cement is mixed with water, the three main components of cement i.e. tri-calcium silicate (C3S), tri-calcium aluminate (C3A), and dicalcium silicate (CsS) react with water. Tri-calcium silicate hydrates more rapidly and develop early strength, generates heat more rapidly and has less resistance to chemical attack. Whereas di-calcium silicate hydrates and hardens slowly; it adds to the ultimate strength and provides more resistance to chemical attack. Tri-calcium aluminate is fast reacting and a large amount of heat generates and causes an initial setting. The phenomenon of changing from a fluid state to a rigid state is called the setting of cement. Hardening of cement due to its hydration, which results in strength development, is different from setting. In concrete construction work, it is specified that the plastic concrete should be placed and consolidated before the initial setting has occurred. It should not be disturbed until it has hardened. The initial setting time should not be too small and therefore the standards specify the minimum initial setting time. After initial setting, the concrete becomes rigid at final setting and thereafter through hardening attains strength rapidly; so there is a minimum of delay before side shuttering can be removed. The setting time measures the time taken for the cement paste to offer a certain degree of resistance to the penetration of a special attachment pressed into it. Two periods of times are used to assess the setting behaviour. These are called initial setting time and the final setting time. The terms initial and final setting set are used to describe arbitrarily chosen stages of setting.

Initial setting time is defined as the period or the time starting from the instant of mixing of water to a state at which the cement paste loses its plasticity. It indicates the end of the slow and steady rate of chemical reaction after which rapid rises in temperature occurs due to the faster rate of the chemical reaction. Practically it is defined as the period elapsing between the time when the water is added to the cement and the time at which a needle of 1 mm square section penetrates no deeper than to a point 5 mm ± 0.5 mm from the bottom of the Vicat apparatus mould with the cement paste. Initial setting time (minimum) as specified by ISI is 30 minutes for ordinary and rapid hardening Portland cement and 60 minutes for low heat cement.

Whereas the final setting time is the time taken to reach the stage when the paste becomes a rigid mass. Practically, it is defined as the elapsing between the time when water is added to the cement and the time at which the needle makes an impression on the surface test block while the annular attachment fails to do so. Note the difference between the attachments for determining the initial and final setting time.

Final setting time (maximum) is 600 minutes for all types of cement according to IS specifications (269-1989, IS 6909-1990, IS 1489-1991).

Final setting time chemically implies a maximum rise of temperature in the sample. The phenomenon of abnormal premature hardening of concrete or cement within a few minutes of mixing of water is called the false setting of cement. In this case, not much heat is evolved and re-mixing without additional water gives the required workability and the cement sets in the normal manner with no appreciable loss of strength. There is no relationship between setting time and rate of strength development of concrete. Final setting time is approximately equal to 90 + 1.2 times initial setting time for normal Portland cement at room temperature.

Equipment

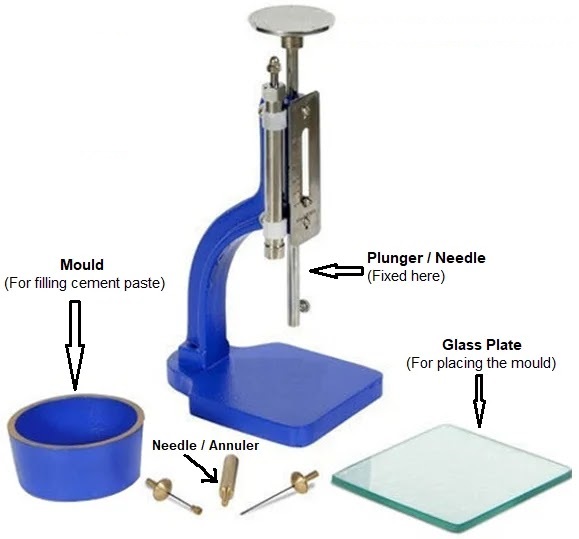

1) Vicat’s apparatus with mould and non-porous plate as per IS: 4031 (Part-V) 1988

2) Needle (C) for initial setting time and needle (F) for final setting time.

3) Balance (capacity 1 kg. Sensitivity 0.1 gram)

4) Trowel (weighing about 210 grams)

5) Enamel tray

6) Standard spatula

7) Stopwatch

8) Thermometer

9) Measuring cylinder, 2 numbers (100 cc)

Materials used

Cement (Ordinary Portland) and water

Procedure

1. Preparation of cement paste (sample):

Weigh 402-450 grams of Ordinary Portland Cement accurately (W) having standard consistency (P). The water which is to be added in the above-weighed cement is 0.85 times the percentage of water required for the standard consistency i.e. 0.85 P x W. Mix it uniformly with a spatula over a glass plate. The mixing or gauging time of cement water is not less than 1 minute and not more than 5 minutes. It is counted from the instant of adding water to dry cement up to the filling of the mould.

2. Determination of Initial setting time:

i) The cement paste as prepared above is filled in Vicat’s mould, which is rested a non-porous plate.

ii) Smooth off the upper surface of the paste, making it level with the top of the mould to give the test block.

iii) The mould resting on a non-porous plate is placed under the rod bearing the needle (C).

iv) Lower the needle gently in contact with the surface of the test block and quickly release the needle allowing it to penetrate into test block. In the beginning, the needle (C) will completely pierce the test block.

v) Repeat this procedure until the reading becomes 5 ± 0.5 mm, measured from the bottom of the mould.

vi) Note the initial setting time.

vii) Record the time in the observation table.

3. Determination of final setting time:

i) Replace the needle (C) (used for initial setting time) of the Vicat’s apparatus with the needle with an annular attachment (F) for the final setting time.

ii) Release the needle gently as described in initial setting time, till the needle makes an impression there on, while the annular attachment fails to do so after about 1½ hour of initial setting at intervals of 10 minutes.

iii) The period elapsing between the time when water is added to the cement and the time at which the needle makes an impression on the surface of test block while the annular attachment fails to do so shall be the final setting time.

iv) Record that time in the observation table.

v) Use the under side of the test block, if a is scum is forming on the surface, for the determination of final setting time.

ALSO READ

- Flash and Fire Points of Bituminous Materials

- Determination of Flakiness and Elongation Index of Coarse Aggregates

- Stripping Value of Road Aggregate by Dynamic Immersion Method

- Determination of Efficiency of a Centrifugal Pump

- Calibration of V-Notch Experiment

- Aggregate Impact Value Test as per IS 2386 (Part-IV) 1993

- Aggregate Crushing Value Test

- Water Content of Soil by Oven Drying Method

Observation

Weight of cement (W) = …………… gm

Standard consistency of water (P) = …………… %

Weight of water to be added = 0.85 x W x P = ……….

| Sl. No. | Time in minutes | Vicat’s apparatus reading |

| 1 | ||

| 2 | ||

| 3 | ||

| 4 | ||

| 5 | ||

| 6 |

Time for initial setting = ……………

Time for final setting = ……………

Precautions

1) The needle should be cleaned every time before use.

2) A proper needle is fixed for initial and final setting time.

3) Release the needle gently after it comes in contact with the surface of test mould.

4) Gauging time should not be less than 3 minutes and not more than 5 minutes.

5) Check up the stopwatch for accuracy.

6) Shift the position of the mould after recording the presentation reading so that the penetration may not be at the same place.

7) Test block should be kept in 90% relative humidity and temperature 27 degree Celsius ± 2 degree Celsius.

8) The experiment should be performed away from vibrations and other disturbances.

Report

1) Drawing the sketches: Sketch of Vicat’s apparatus, with needle C and F.

Hi! I hope you are doing great. Thanks for sharing such a great article in astonishing formate.

You Welcome